Top 10 Textile ERP Benefits: Why You Should Implement?

In the textile industry, staying competitive depends on operating with high efficiency, adaptability, and precision. One of the most effective ways to achieve this is through ERP implementation. By integrating ERP software, textile manufacturers can streamline operations, enhance productivity, and manage resources with better accuracy.

In this blog, we’ll explore the top 10 benefits of ERP implementation in your textile business and discuss how it can transform your operations, helping you achieve higher efficiency and profitability.

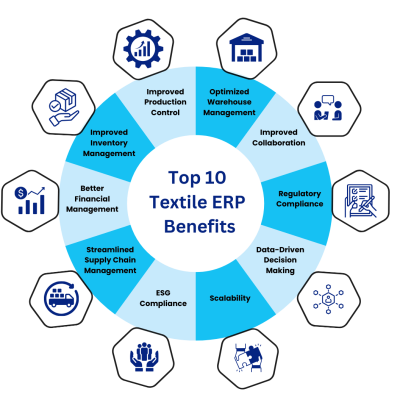

Top 10 Textile ERP Benefits

Implementing an ERP system tailored specifically for textile operations brings a wide array of advantages, from better production and inventory management to streamlined financial processes.

Below, we dive into the top 10 benefits of ERP implementation for textile businesses and explain how it can reshape your company’s operational landscape to keep up with industry demands.

- Improved Production Control

- Improved Inventory Management

- Better Financial Management

- Streamlined Supply Chain Management

- Stay Compliant with ESG Standards

- Scalability

- Data-Driven Decision Making

- Regulatory Compliance

- Improved Collaboration

- Optimized Warehouse Management

1] Improved Production Control: ERP implementation allows textile manufacturers to optimize the entire production process by providing real-time tracking of production activities. With an ERP system in place, manufacturers can monitor each stage of the manufacturing process, identify bottlenecks, and ensure that each phase operates seamlessly.

This heightened level of control reduces delays, minimizes errors, and ensures that delivery deadlines are consistently met. By enhancing production control, textile businesses can better manage various orders, prevent disruptions, and improve overall operational flow.

2] Improved Inventory Management: ERP textile advantages are especially valuable in inventory management, which is crucial in an industry dealing with a wide variety of raw materials, colors, and product types. An ERP system provides an accurate, real-time view of stock levels, helping businesses avoid overstocking and understocking.

Automated tracking of raw materials, in-process inventory, and finished goods allows companies to reduce waste, cut down on storage costs, and improve overall supply chain management. This enhanced inventory control not only reduces costs but also enables better resource allocation, ensuring that production runs smoothly without interruptions due to stock shortages.

3] Better Financial Management: ERP implementation in a textile business greatly improves financial management by automating accounting, budgeting, and reporting processes. This reduces manual errors, speeds up financial reporting, and provides a clearer picture of the company’s financial health.

With real-time visibility into cash flow and expenses, ERP software empowers decision-makers to manage cash flow more effectively and generate accurate financial statements. These insights are crucial for strategic planning and help companies make informed decisions that drive growth and profitability.

4] Streamlined Supply Chain Management: One of the core ERP textile advantages is its ability to streamline supply chain management. ERP software connects each element of the supply chain, from raw material procurement to product delivery.

This integration facilitates better coordination between suppliers, manufacturers, and distributors, enabling textile businesses to reduce lead times, control costs, and expedite product deliveries to market. By improving supply chain transparency and efficiency, ERP implementation allows textile businesses to respond quickly to demand fluctuations and maintain strong relationships with suppliers and customers.

5] Stay Compliant with ESG Standards: Environmental, Social, and Governance (ESG) standards are becoming more important in the textile industry. With growing consumer demand for ethical and sustainable products, companies must demonstrate that they meet these standards.

An ERP software helps textile businesses stay compliant by tracking materials, ensuring sustainable sourcing, and generating reports that show compliance with various ESG regulations. This boosts the company’s reputation and opens doors to new markets focused on sustainability.

6] Scalability: As textile businesses expand, their operational needs become more complex. One of the standout ERP textile advantages is scalability, which allows for seamless adjustments and additions as your business grows.

Whether increasing production capacity, entering new markets, or diversifying product lines, ERP implementation provides a flexible framework that can accommodate your evolving needs. New modules and features can be added without disrupting existing processes, ensuring smooth operations regardless of growth or market changes.

7] Data-Driven Decision Making: An ERP system provides real-time data across departments, enabling data-driven decision making that’s faster and more accurate. By accessing comprehensive reports and dashboards highlighting key performance metrics, decision-makers can identify trends, optimize production schedules, and make adjustments to boost profitability.

Instead of relying on guesswork, textile companies can make strategic choices based on accurate data, empowering them to respond to challenges proactively and stay competitive.

8] Regulatory Compliance: In the textile industry, adhering to regulatory standards is essential, covering areas like health and safety, labor laws, and environmental requirements. ERP implementation helps businesses stay compliant by automating compliance tracking and generating detailed reports for regulatory bodies. This functionality reduces the risk of penalties, audits, and reputational damage, ensuring that your business remains within the legal framework while focusing on its growth and development.

9] Improved Collaboration: One of the challenges in textile businesses is ensuring collaboration across different departments, such as production, sales, and customer service. ERP software fosters better communication and teamwork by providing a centralized platform where all departments can access the same information in real-time. This connectivity improves collaboration, accelerates problem-solving, and ensures that everyone is aligned on goals and objectives, ultimately creating a cohesive and responsive business environment.

10] Optimized Warehouse Management: Managing a textile warehouse involves handling a diverse range of products and materials. ERP implementation optimizes warehouse management by automating tasks like inventory tracking, picking, and shipping, significantly reducing human error and boosting efficiency. This optimization leads to faster order fulfillment, reduced storage costs, and higher customer satisfaction. By streamlining warehouse operations, ERP software ensures that your warehouse is well-organized and capable of supporting timely deliveries and seamless operations.

In textile industry, efficiency and adaptability are key to staying competitive. ERP implementation provides numerous benefits to textile businesses, from enhanced production control and improved financial management to compliance with ESG standards. By centralizing operations, enabling data-driven decision making, and fostering collaboration, ERP systems help textile companies reduce costs, boost customer satisfaction, and achieve sustainable growth. Whether you’re a small textile manufacturer or a large enterprise, ERP implementation is a valuable investment that will pay dividends in improved processes, scalability, and resilience in a dynamic industry.