Optimizing Production Scheduling with ERP Manufacturing Software

Efficient textile production planning and scheduling is a long-standing struggle for textile manufacturers due to the complexities involved. This necessitates getting all the right tools to manage this process. One of the most common tools is ERP manufacturing software.

This blog will talk about the aspect of ERP production scheduling and how it acts as an asset to your textile production processes.

What is ERP Manufacturing Software?

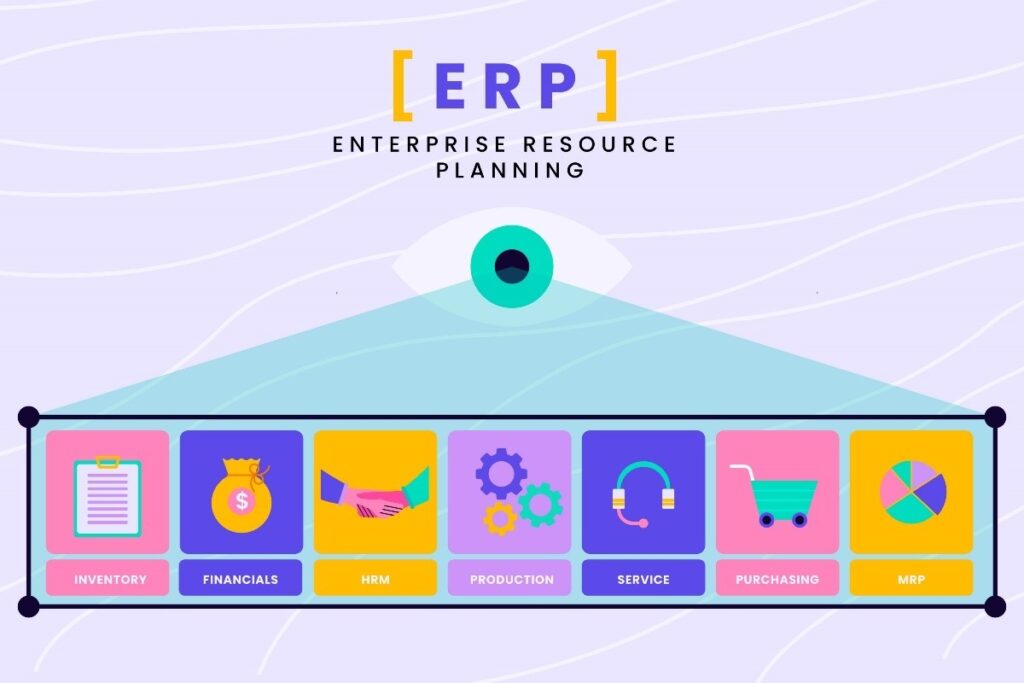

ERP is a software designed to make sure the resources of a textile manufacturing company are used efficiently, and the customer demands are met in time. These software systems usually come equipped with modules such as:

- Production Planning and Scheduling

- Inventory Management

- Supply Chain Management

- Quality Management

- Production Entry

Efficient textile production planning and scheduling is a long-standing struggle for textile manufacturers due to the complexities involved. This necessitates getting all the right tools to manage this process. One of the most common tools is ERP manufacturing software.

This blog will talk about the aspect of ERP production scheduling and how it acts as an asset to your textile production processes.

Challenges in Optimizing Production Scheduling in Textile Industry

Here are some of the major obstacles that textile manufacturers face in optimizing production scheduling in their textile business:

- Rapidly Evolving Trends: High variability in orders and resource allocation makes standardized production scheduling difficult. This is due to a wide range of custom orders, each with unique specifications such as fabric type, color, design, and size.

- Demand Forecasting: Customer demand for textile products can fluctuate easily and is difficult to forecast accurately. Seasonal trends, fashion changes, and market conditions lead to changes in demand, making it difficult to maintain the right inventory levels.

- Raw Material Sourcing: Ensuring reliable and timely supply of raw materials is challenging. This is mainly because sourcing raw materials from global suppliers often involves long lead times influenced by factors like distance, logistics, vendor reliability, etc.

- Quality Control: Maintaining consistent quality across diverse production batches and ensuring compliance with textile industry standards is complicated. Different suppliers may provide raw materials that vary in quality, which can lead to inconsistencies in production.

- Customer Retention: Meeting diverse customer expectations and handling custom orders efficiently to retain loyalty and satisfaction can get tricky. Customer orders usually come with unique specifications, such as different sizes, colors, designs, and materials. Managing these variations requires precise planning and scheduling.

- ESG compliance: Implementing sustainable and ethical practices while balancing production efficiency and cost-effectiveness is complex. ESG standards include integrating sustainable practices, reducing environmental impact, ensuring fair labor practices, and maintaining transparency.

How Textile ERP Solutions Optimize Production Scheduling?

Now that we know what obstacles textile manufacturers face during production scheduling processes, lets discuss how ERP manufacturing software will solve them.

1) Real-time Monitoring and Control: Textile ERP software assists users to track status of each production order, providing visibility into production stages and identifying bottlenecks. It integrates with various sensors, machine interfaces, and manual inputs to collect real-time data such as Machine Status, Labor Tracking and Inventory Levels to monitor the status of all operations.

2) Dynamic Adjustments: ERP systems help manufacturers modify production schedules in real-time using data from various sources such as shop floor sensors, RFID tags, and manual inputs in scenarios of variations in demands or any sudden machine breakdowns. This data includes Production Progress, Machine Utilization, Material and Labor Availability.

3) Demand Forecasting: ERP integrates Production Data, Inventory Data and External Data present within the organization to conduct real-time and historical analysis. The software helps users to perform predictive analysis by using historical data and market trends to forecast future demand for products and materials.

4) ESG Integration: ERP helps manufacturers adhere to ESG principles in the textile industry facilitating sustainability, ethical practices, and long-term viability. ERP software enhances ESG reporting by using integrated data, real-time KPI monitoring, and customizable reports, ensuring accurate, comprehensive, and tailored sustainability metrics for effective communication.

Key Features of ERP Solutions for Production Scheduling

Now let’s see some of the key features of ERP manufacturing software that helps you optimize your production scheduling processes:

1) Advanced Planning and Scheduling (APS)

The APS feature of a textile ERP implements advanced algorithms to balance production capacity with demand.

- These algorithms assist the user to allocate resources efficiently, considering machine capabilities, labor skills, and material availability.

- APS also integrates Demand Planning, Production Planning, Detailed Scheduling and Sequence Optimization to create an optimized production schedule.

2) Inventory Management

ERP manufacturing software integrate inventory management with production scheduling through Material Requirements Planning (MRP) functionality.

- It enables traceability and tracking of materials throughout the supply chain and production process to ensure quality consistency.

- This helps to maintain a regular check on product quality in a fast and efficient way making the production schedule effective.

3) Quality Management Integration

With integrated quality management, an ERP manufacturing software defines quality standards and performs quality control checks.

- ERP software enables users to track quality metrics, manage inspections, and ensure compliance with industry regulations.

- This helps to establish a standard for all production processes and integrate quality control checkpoints at various stages of production to identify defects early.

4) Supply Chain Coordination

ERP systems facilitate supplier integration through seamless communication with suppliers to ensure timely delivery of raw materials.

- Performance metrics such as on-time delivery, quality consistency, and compliance with contractual terms are tracked within the ERP system.

- ERP systems automate procurement processes based on production schedules, inventory levels, and reorder points.

5) Production Entry

Textile ERP systems help manufacturers ensure the accurate recording, tracking, and management of production activities through automated production entry.

- This feature is essential for optimizing production scheduling as it ensures that all production data is captured in real-time, enabling effective planning, monitoring, and control of manufacturing processes.

- The software promotes Work Order Management, Real-Time Data Entry, Work-in-Progress (WIP) Tracking and maintenance of Inspection Records.

How to Choose the Right ERP Software for Your Manufacturing Business?

Choosing the right ERP manufacturing software is a confusing task as there are so many options in the current market. You will need a general guide or a roadmap on how to choose the best ERP software available that best suits your textile business. Let us look at the common stages involved in selecting a suitable ERP software:

- Assess business needs with a selection committee

- Define a budget

- Research and evaluate potential vendors

- Assess the product of the vendors

- Assess the credibility of the selected vendors

- Evaluate support and training

- Perform a legal agreement

Implementing ERP manufacturing software in the textile industry optimizes production scheduling by addressing key challenges such as demand variability, raw material sourcing, and quality control. Through real-time monitoring, dynamic adjustments, and advanced planning, ERP systems streamline processes, ensuring efficiency and timely deliveries.

The integration of ESG principles further promotes sustainability and ethical practices. Features like inventory management, quality management integration, and supply chain coordination, textile manufacturers can optimize production, maintain quality, and meet customer expectations, ultimately driving operational excellence and competitive advantage.