Managing Complex Upholstery Supply Chains with ERP Software

In the process of upholstery manufacturing, managing upholstery supply chains is by far the most tedious to handle. Over 56% of U.S. furniture manufacturers report persistent difficulty in sourcing materials and managing supplier timelines, particularly for upholstery-grade textiles and foam. From sourcing unique fabrics to fulfilling highly customized orders, managing the upholstery supply chain involves a lot of complications. As customer expectations grow and global operations become more intricate, upholstery manufacturers are turning to technologies such as ERP software to bring clarity, control, and consistency to their upholstery supply chains.

Key Supply Chain Issues Faced by Upholstery Manufacturers

Supply chain management in upholstery manufacturing involves a vast array of materials. Each order often demands a different combination of these components, along with specific colors, finishes, and delivery timelines. As product personalization increases, the need to manage this complexity becomes even more critical. Let’s look at the major pain points that can slow down or disrupt upholstery supply chains:

- Inventory Mismatches and Material Shortages: Manual tracking often leads to inaccurate stock counts, resulting in delays or excess holding costs.

- Delayed Shipments and Order Backlogs: Without centralized scheduling, overlapping orders or supplier delays can quickly create bottlenecks.

- Lack of Real-Time Coordination: Production, procurement, and sales often operate in silos, leading to miscommunication and misalignment.

- Vendor Unreliability and Quality Inconsistencies: When supplier performance isn’t monitored, late deliveries and quality issues become common.

How ERP Software Streamlines Upholstery Supply Chains

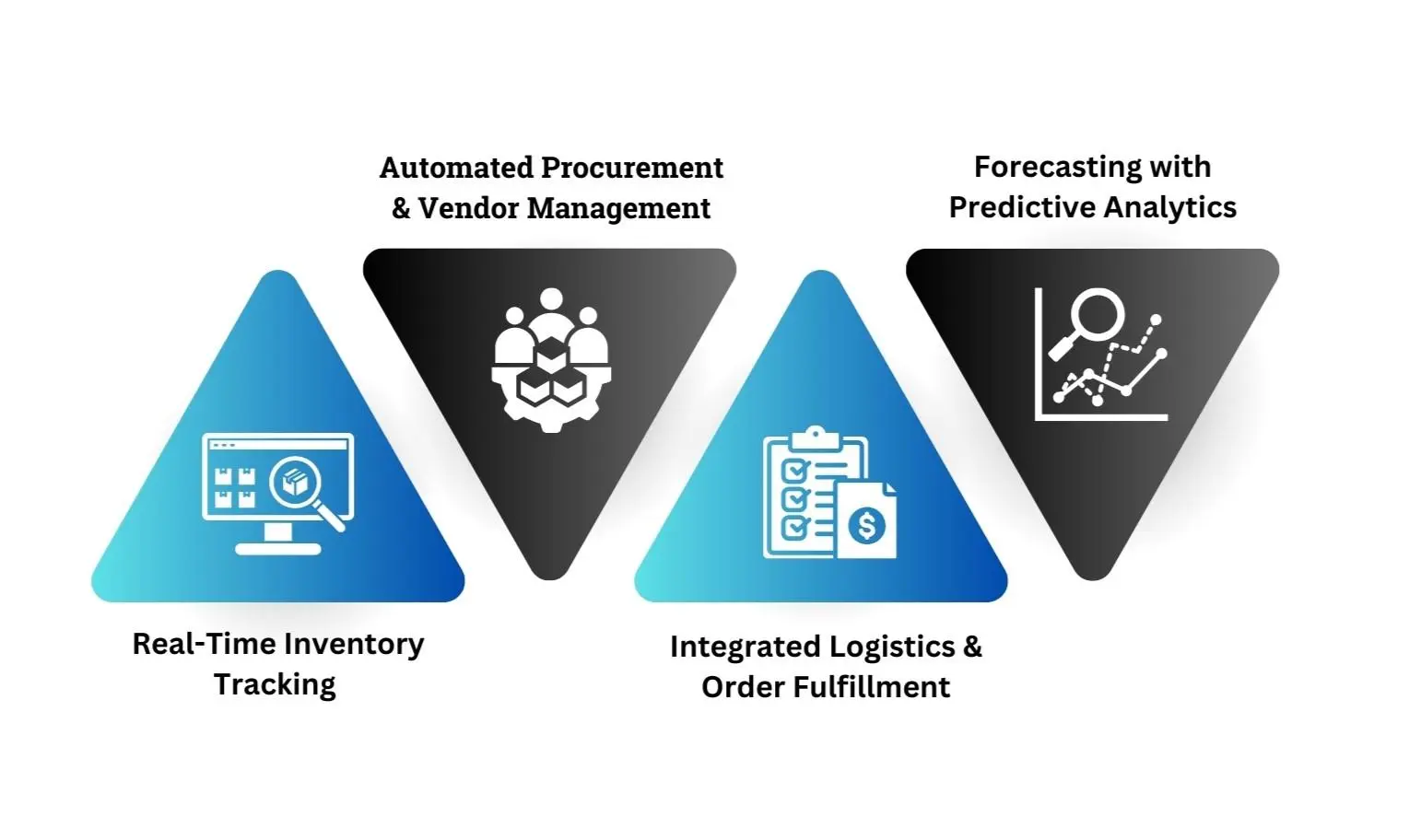

Modern ERP software is designed to integrate and optimize every part of the upholstery supply chain. Here’s how it makes a difference:

Real-Time Inventory Tracking

- One of the most valuable features of ERP software in managing complex upholstery supply chains is real-time inventory tracking. Supply chain management in upholstery involves dozens of components — different fabrics, stitching styles, fabric dyes, and finishes. Keeping track of all these materials and processes manually is prone to error and can lead to costly disruptions.

- Real-time inventory upholstery ERP centralizes your inventory data across all warehouses and production units, giving you a live view of what’s in stock, what’s reserved for existing orders, and what needs to be reordered. Whether it’s raw materials, semi-finished parts, or finished goods, every item is monitored in real time.

Automated Procurement and Vendor Management:

- In the upholstery industry, delays or inconsistencies from even a single vendor can disrupt the entire production schedule. That’s why automated procurement and vendor management are critical functions of modern ERP software.

- With upholstery ERP, the entire procurement process becomes more streamlined, and data driven. The system tracks usage trends and stock levels and can automatically generate purchase orders when materials reach predefined reorder points. This minimizes the risk of last-minute shortages and helps maintain a steady flow of materials into production.

Integrated Logistics and Order Fulfillment:

- In the upholstery industry, timely and accurate order fulfillment is just as critical as high-quality craftsmanship. Delays in delivery, mismatched products, or missing components can damage customer satisfaction and hurt your reputation. ERP software addresses these challenges by tightly integrating logistics, warehouse operations, and order processing into one seamless workflow.

- With a centralized system, every stage of the fulfillment process is interconnected—right from when the order is placed to when it’s shipped and invoiced. This integration reduces communication gaps, manual errors, and operational silos that often slow down traditional upholstery businesses.

Forecasting with Predictive Analytics:

- By analyzing past order trends, seasonality, and market behavior, ERP systems help you plan. This means better demand forecasting, fewer surprises, and smarter resource allocation.

- This forecasting capability allows manufacturers to align procurement, production, and staffing with actual demand patterns. For instance, if data reveals that a particular fabric or sofa model sees higher demand in the winter season, the ERP system can alert production planners to prepare in advance, avoiding delays and stockouts.

Benefits of Using an ERP System

Implementing ERP software brings measurable benefits that directly impact profitability and growth:

- Faster Production Cycles: When materials and workflows are synchronized, products move through production without unnecessary delays.

- Reduced Waste and Cost Control: With accurate data, you can prevent over-ordering and cut down on material waste, leading to better margins.

- Stronger Supplier Relationships: ERP allows for better communication and evaluation of vendors, encouraging reliability and accountability.

- Higher Customer Satisfaction: On-time deliveries, consistent quality, and the ability to handle special requests build trust and encourage repeat business.

- Scalability: As your upholstery business grows, your ERP system scales with you — whether you’re adding new product lines, entering new markets, or working with more suppliers.

As the markets are becoming more customer-driven, upholstery manufacturers can’t afford to rely on outdated systems or manual tracking. Supply chain complexity will only increase, and the businesses that thrive will be those that embrace leveraging AI in their upholstery manufacturing processes.

AI integrated ERP software like iTexClouds helps upholstery manufacturers with the tools they need to handle this complexity, from better inventory and vendor management to smarter forecasting and faster order fulfillment. It turns a fragmented supply chain into a well-oiled machine, allowing companies to increase efficiency, reduce costs, and meet evolving customer expectations.

If you’re looking to gain full control of your supply chain and grow your upholstery business, an ERP tailored to your needs is no longer optional, it’s essential.