How Smart Upholstery Manufacturing is Transforming the Industry?

The global upholstery market is projected to surpass $60 billion by 2027, driven by rising demand for customized furniture, eco-conscious materials, and smart home integration. As consumer preferences continue to shift, traditional upholstery processes are being challenged. This is where smart upholstery manufacturing is stepping in—redefining efficiency, quality, and creativity in furniture production. In this blog, we explore how smart technologies are revolutionizing upholstery manufacturing and what it means for the future of the industry.

Advantages of Smart Upholstery Manufacturing

Smart upholstery manufacturing refers to the use of modern technologies like AI, IoT, automation, and data analytics in the production of upholstery materials. These technological advancements enable real-time decision-making, predictive maintenance, custom design integration, and improved material usage. Manufacturers are now moving away from guesswork and manual operations, adopting digital systems that optimize every aspect of the production cycle.

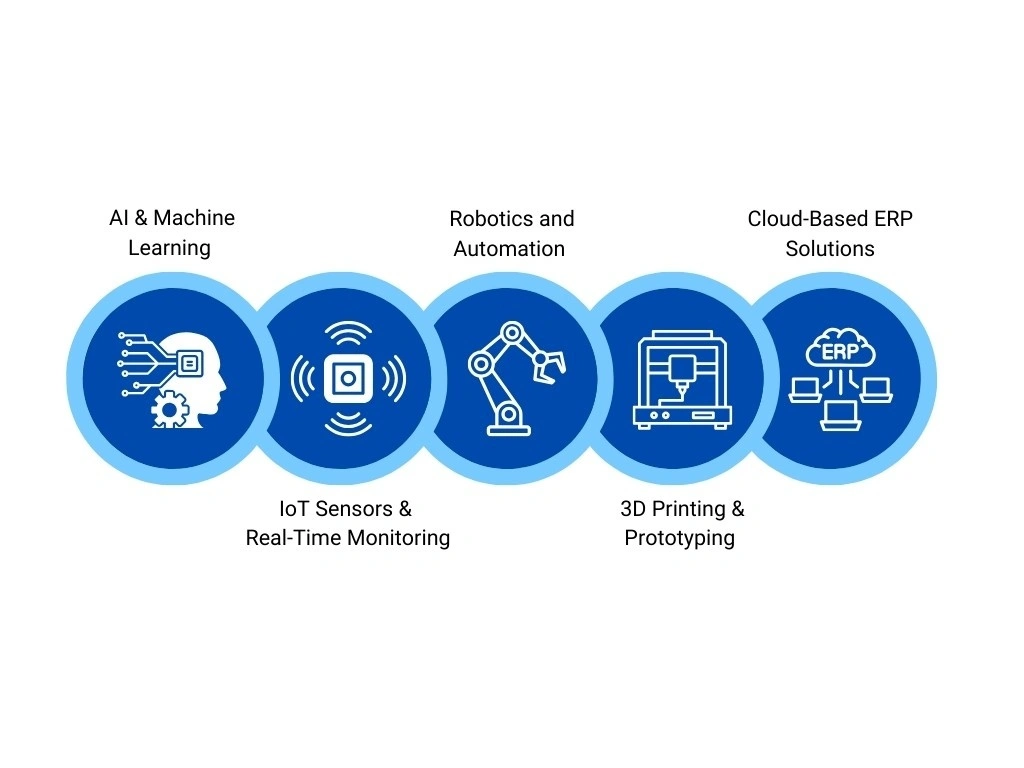

Key Technologies Driving the Transformation

As the upholstery industry undergoes a technological revolution, several advanced systems are emerging as game-changers. These technologies are not only enhancing the speed and accuracy of production but also redefining how manufacturers respond to consumer demands, market trends, and sustainability goals. Let’s take a closer look at the technologies that are driving this transformation:

AI and Machine Learning

AI-powered design software helps manufacturers predict trends, analyze customer behavior, and recommend fabric combinations or patterns that are likely to sell. Machine learning algorithms can also optimize cutting patterns, reducing material waste and speeding up production timelines.

IoT Driven Real-Time Monitoring

Smart sensors attached to machinery can monitor wear and tear, predict failures, and ensure optimal usage. IoT devices also help track the status of every order in real time, improving transparency and reducing communication gaps between teams.

Robotics and Automation

From automated fabric cutters to robotic arms used in stitching or assembling, automation drastically reduces manual labor. This not only improves consistency in product quality but also speeds up large-scale production.

3D Printing and Prototyping

3D printing technology allows for rapid prototyping and testing of new furniture designs. Upholstery manufacturers can experiment with shapes and sizes without incurring huge sample costs or delays.

Cloud-Based ERP Solutions

Modern ERP Systems for Upholstery Manufacturers offer modules for material planning, order tracking, inventory control, and vendor management—all in one platform. Cloud-based access enables real-time collaboration across departments and locations.

Challenges in Adopting Smart Technology

Despite the promise of increased efficiency, quality, and innovation, transitioning to smart upholstery manufacturing comes with its own set of challenges. These obstacles can slow down adoption and create friction across different areas of the business. Understanding these challenges is the first step toward overcoming them:

- High Initial Investment: The cost of implementing IoT, robotics, or ERP systems can be significant.

- Workforce Adaptation: Employees need training to work alongside new technologies and systems.

- Data Integration: Connecting old machinery with new digital tools requires careful planning and compatibility checks.

- Cybersecurity Risks: As operations go digital, protecting company data and production systems becomes crucial.

Benefits of Smart Upholstery Manufacturing

Despite the promise of increased efficiency, quality, and innovation, transitioning to smart upholstery manufacturing comes with its own set of challenges. These obstacles can slow down adoption and create friction across different areas of the business. Understanding these challenges is the first step toward overcoming them:

By embracing smart technologies like an ERP software for upholstery manufacturing, manufacturers can access a wide range of benefits:

- Reduced Production Costs: Automation and real-time data reduce material waste and downtime.

- Improved Quality Control: Consistent monitoring ensures defects are caught early.

- Faster Time to Market: Predictive analytics and AI-assisted planning help meet seasonal demand quicker.

- Enhanced Customization: Digital design tools allow for quick adaptation to consumer preferences.

- Sustainable Production: Optimized material usage and predictive maintenance support eco-friendly practices.

The Future of Upholstery Manufacturing

The adoption of smart technology in upholstery production marks a significant step forward, but it’s only the beginning. As innovation accelerates, the future holds even more exciting developments that promise to reshape the industry on a larger scale. Here’s a look at some of the emerging trends and possibilities that are poised to redefine how upholstery products are designed, manufactured, and delivered:

- AI-powered design assistants recommending entire furniture collections based on customer demographics.

- Voice-activated production lines integrating with smart home systems.

- Sustainable digital twins that simulate production outcomes before any real-world execution.

- Hyper-customization at scale, where customers configure their upholstery pieces online and receive them within days.

As smart homes and AI assistants become part of everyday life, the demand for intelligent, well-designed, and responsive upholstery will only grow.

Smart upholstery manufacturing is no longer a futuristic concept—it’s happening now. By leveraging technologies like AI, IoT, robotics, and cloud ERP systems, upholstery manufacturers are cutting costs, improving quality, and adapting faster to consumer demands. Though challenges exist, companies that begin adopting these technologies today will be better positioned to lead the market tomorrow.

In 2025 and beyond, the winners in the upholstery industry will be those who innovate with purpose, embrace data-driven decisions, and commit to building smarter, more responsive operations.