All Resources

Read and get updated on how we progress

- All Resources

- Blog

- Customer Story

The upholstery industry is evolving fast in 2025 and is predicted to grow at a CAGR of over 5.5%, reaching $27.58 billion by 2030. With rising customer expectations, tighter delivery timelines, and growing demand for customization, upholstery businesses must rethink how they operate.

Relying on outdated methods is no longer sustainable or optimum. That’s where upholstery manufacturing ERP software plays a key role. It helps streamline operations, reduce errors, and improve margins across every stage of production and delivery.

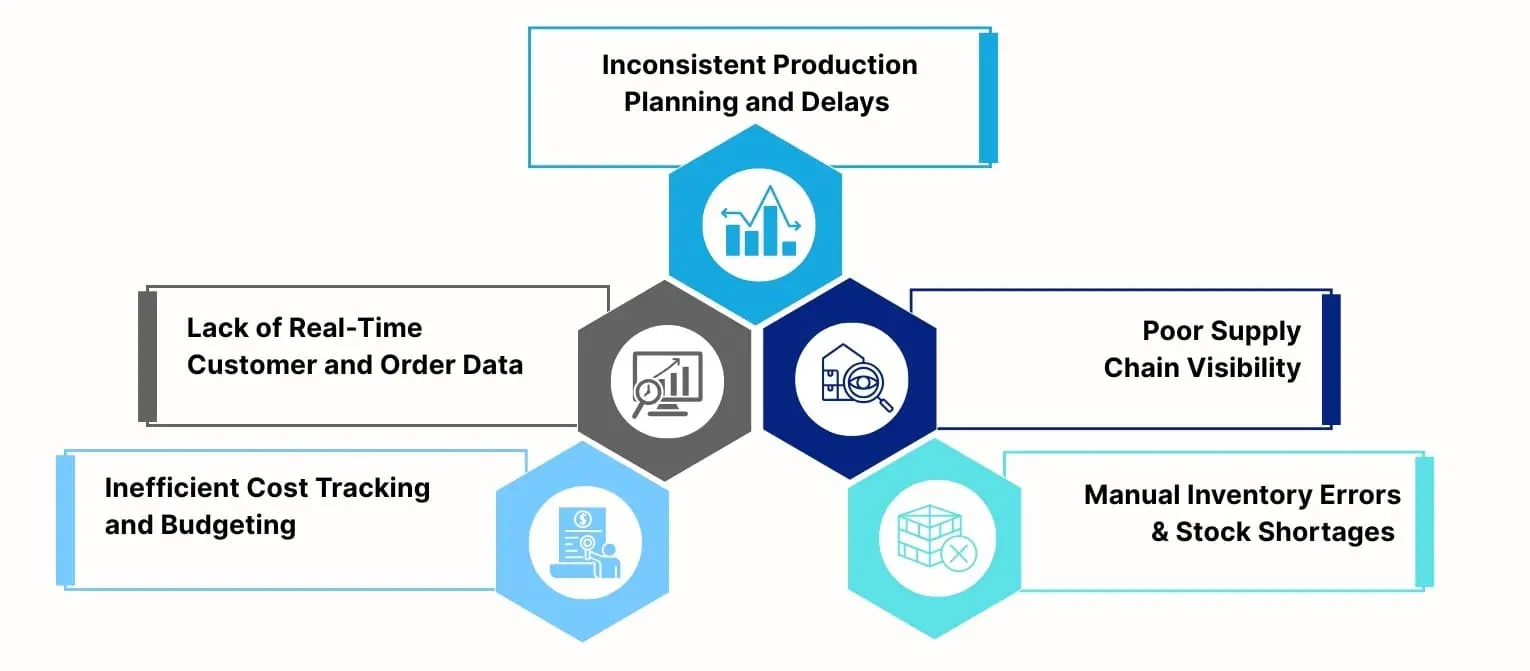

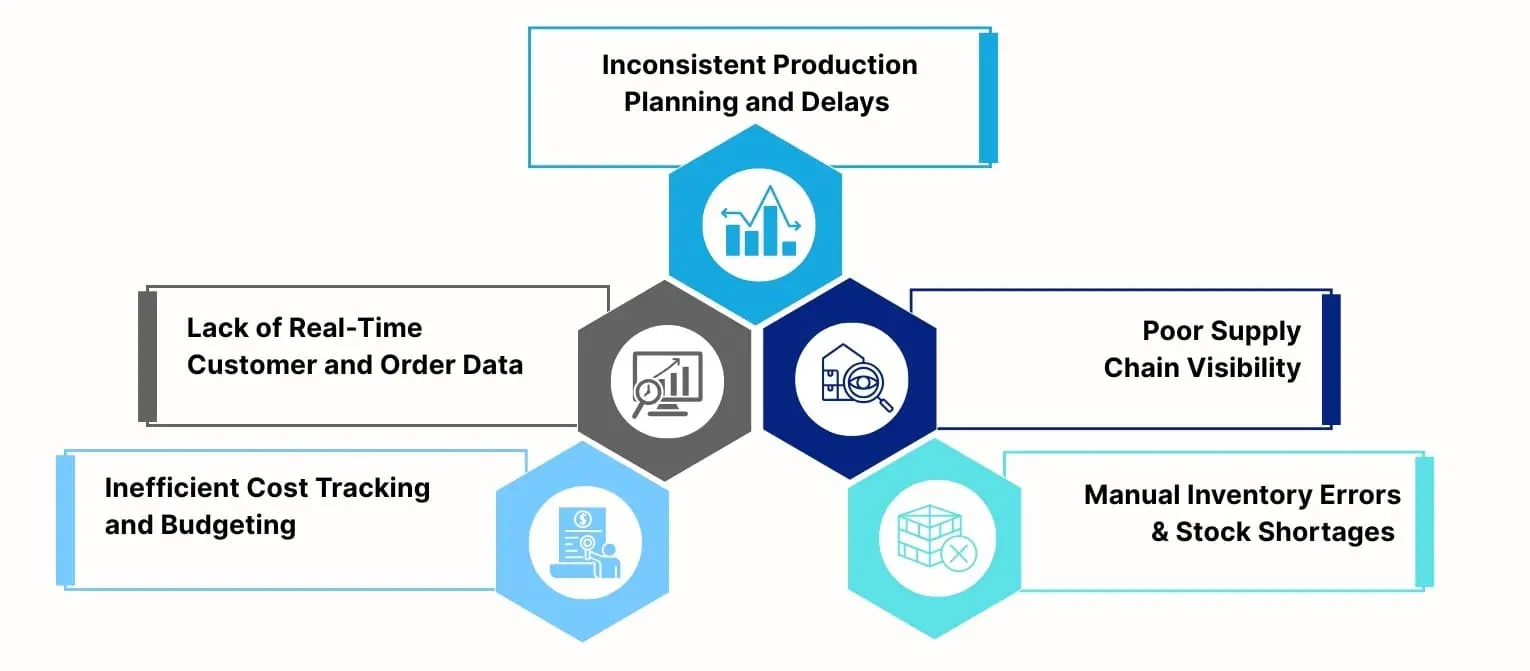

Challenges of Sticking to the "Traditional Ways"

Manual Inventory Errors and Stock Shortages

Upholstery production involves a wide range of materials that are involved in a wider range of processes every step of the way. So, without an automated system, tracking materials becomes a huge task and also prone to a lot of errors. Missing raw materials or overstocking cuts into profits leading to unnecessary delays.

Inconsistent Production Planning and Delays

Paper-based schedules or spreadsheets have their advantages, but they definitely can’t keep up with fluctuating orders and workforce changes that always happen in upholstery manufacturing. Paper-based schedules are also prone to physical damage or tampering, creating a good chance for bottlenecks and missed deadlines to occur.

Lack of Real-Time Customer and Order Data

Traditional systems don’t offer a full picture of customer interactions or order histories. To keep up with the current upholstery market trends, knowing what your customers’ preferences are plays a huge role. Without real-time customer and order data, it limits the ability to personalize service and predict future upholstery demands.

Poor Supply Chain Visibility

Managing suppliers and vendors in an old-fashioned way creates a lot of opportunities for communication gaps. If your suppliers, vendors, and internal teams aren’t connected through a unified system, there will always be a lack of visibility on the upholstery supply chain. This will inevitably lead to errors in customer orders and delivery issues.

Inefficient Cost Tracking and Budgeting

Keeping track of financial data through manual methods is always a tedious task. When it comes to upholstery manufacturing or upholstery production, it gets even more tricky. Without centralized financial data, it's hard to track costs accurately or understand where resources are being wasted.

Key Features of an Upholstery ERP Software for the 2025 Market

Real-Time Inventory and Material Tracking

In textile upholstery manufacturing, managing a wide variety of fabrics, threads, linings, and embellishments can be overwhelming. An ERP system offering inventory management features help with real-time visibility into raw materials, in-process fabrics, and finished goods.

These tools centralize stock data from cutting, stitching, and finishing units, ensuring you never run out of high-demand fabrics or slow-moving ones. With instant updates on stock levels and automated reorder alerts, production teams can operate with fewer delays and tighter inventory control.

AI-Based Production Scheduling and Optimization

Fabric upholstery often involves made-to-order designs with varying textures, colors, and finishes - making production planning more complex. An upholstery manufacturing ERP integrated with AI helps simplify this by automatically creating and adjusting schedules based on order priority, machine availability (like cutting or sewing stations), and material readiness.

This helps to reduce manual planning errors, prevent bottlenecks in fabric handling and processing, and ensure timely order fulfillment, even in high-mix, low-volume production setups.

Built-in Quality Control

An upholstery manufacturing ERP with integrated quality control modules allows manufacturers to define quality checkpoints - whether it’s fabric strength, color consistency, or stitching precision.

These checkpoints are tracked throughout the production process, with real-time alerts for defects or deviations. This ensures that only materials meeting set standards move forward, reducing costly rework and returns. With better visibility into quality metrics, manufacturers can uphold brand standards and improve customer satisfaction over time.

Smart Supplier and Vendor Management

Sourcing fabrics, threads, dyes, and trims from multiple suppliers comes with challenges - especially when quality and lead time directly affect production timelines. An upholstery manufacturing ERP helps manage supplier performance by tracking delivery accuracy, pricing, and defect rates.

With these insights, manufacturers can make informed sourcing decisions, minimize disruptions, and ensure they’re always working with reliable partners. During fabric shortages or price fluctuations, the system helps you quickly identify alternate suppliers without compromising deadlines.

Advanced Analytics and Forecasting Tools

Textile upholstery manufacturing must respond to trends in color, texture, and consumer preferences - often with little notice. Advanced ERP analytics help you spot these trends early by analyzing historical order patterns, seasonal demand, and fabric usage rates.

Whether you're preparing for a seasonal surge in velvet sofas or responding to growing interest in sustainable fabrics, forecasting tools give you the edge. You can better align procurement, optimize fabric rolls, and plan workforce allocation - all while keeping costs in check.

Results You Can Expect

By adopting an upholstery manufacturing ERP such as iTexClouds, businesses can expect more than just automation. You gain end-to-end visibility, improve collaboration, and respond faster to customer needs. Teams spend less time fixing errors and more time focusing on growth. Profit margins increase through better planning, fewer delays, and optimized resource use. Most importantly, you stay competitive in a rapidly changing market.

The upholstery market in 2025 is defined by speed, precision, and personalization. To meet these demands, manufacturers must leave behind traditional workflows. Implementing a powerful ERP system is no longer a luxury. It’s a strategic move to stay relevant, efficient, and profitable.

In the process of upholstery manufacturing, managing upholstery supply chains is by far the most tedious to handle. Over 56% of U.S. furniture manufacturers report persistent difficulty in sourcing materials and managing supplier timelines, particularly for upholstery-grade textiles and foam. From sourcing unique fabrics to fulfilling highly customized orders, managing the upholstery supply chain involves a lot of complications. As customer expectations grow and global operations become more intricate, upholstery manufacturers are turning to technologies such as ERP software to bring clarity, control, and consistency to their upholstery supply chains.

Key Supply Chain Issues Faced by Upholstery Manufacturers

Supply chain management in upholstery manufacturing involves a vast array of materials. Each order often demands a different combination of these components, along with specific colors, finishes, and delivery timelines. As product personalization increases, the need to manage this complexity becomes even more critical. Let’s look at the major pain points that can slow down or disrupt upholstery supply chains:

- Inventory Mismatches and Material Shortages: Manual tracking often leads to inaccurate stock counts, resulting in delays or excess holding costs.

- Delayed Shipments and Order Backlogs: Without centralized scheduling, overlapping orders or supplier delays can quickly create bottlenecks.

- Lack of Real-Time Coordination: Production, procurement, and sales often operate in silos, leading to miscommunication and misalignment.

- Vendor Unreliability and Quality Inconsistencies: When supplier performance isn’t monitored, late deliveries and quality issues become common.

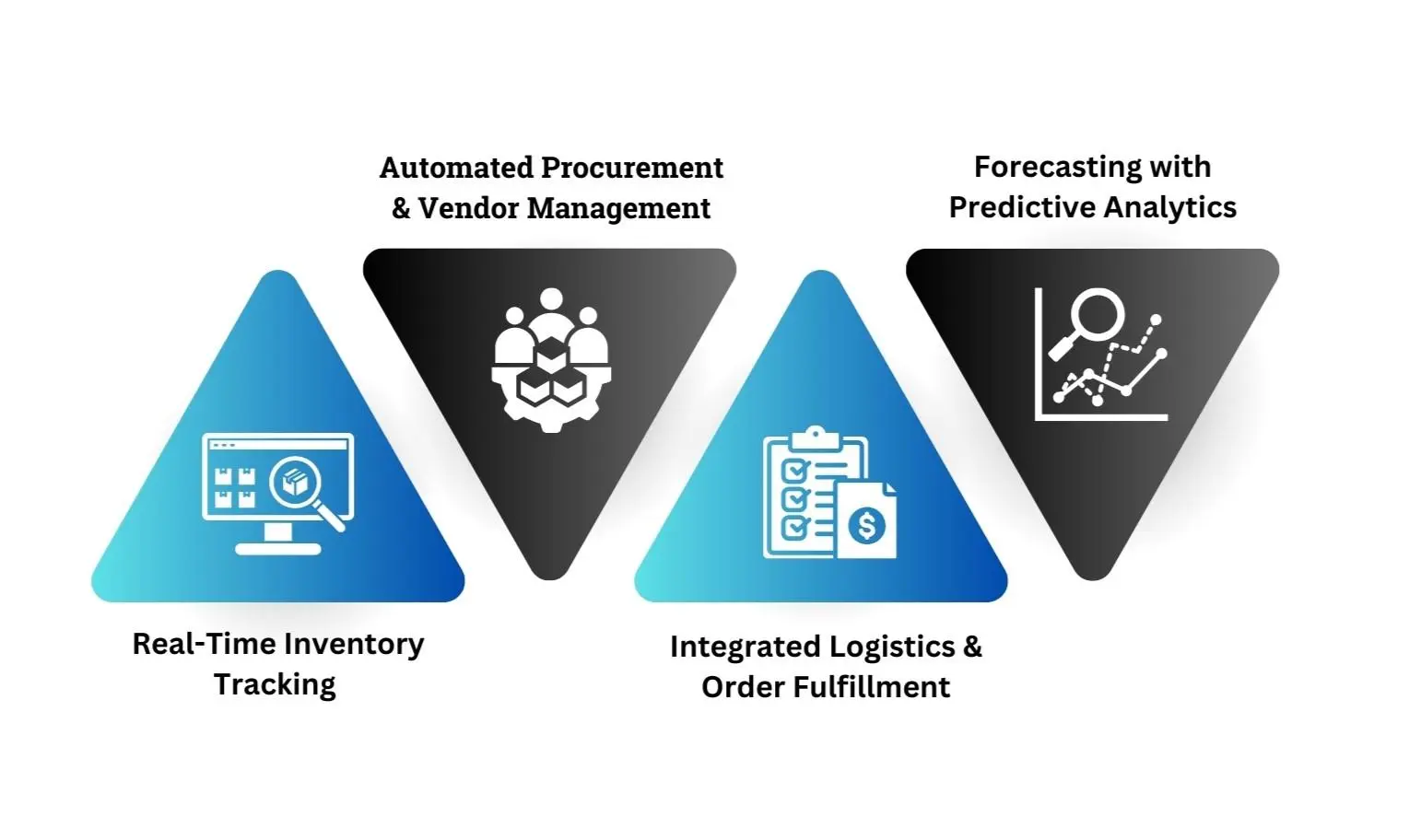

How ERP Software Streamlines Upholstery Supply Chains

Modern ERP software is designed to integrate and optimize every part of the upholstery supply chain. Here’s how it makes a difference:

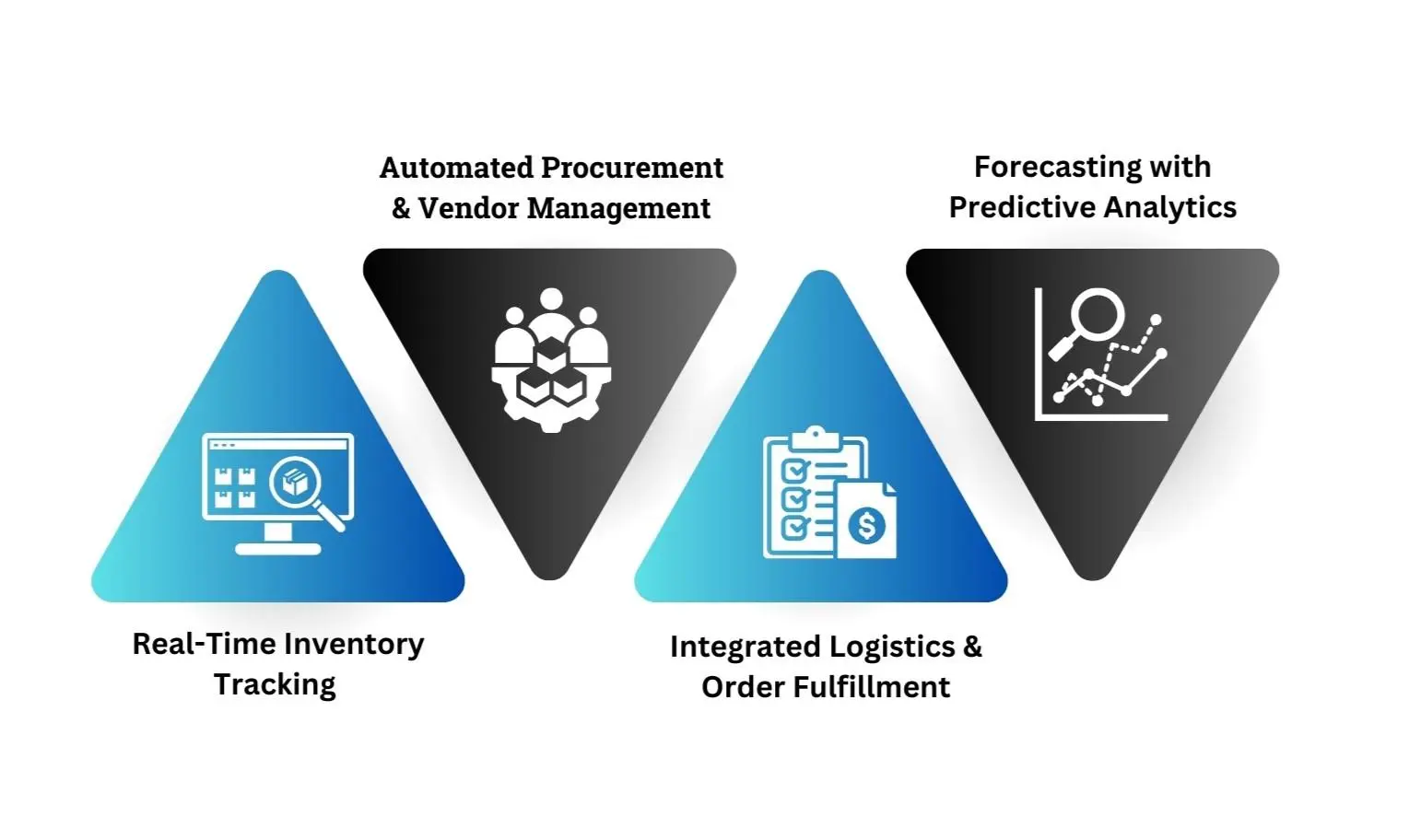

Real-Time Inventory Tracking

- One of the most valuable features of ERP software in managing complex upholstery supply chains is real-time inventory tracking. Supply chain management in upholstery involves dozens of components — different fabrics, stitching styles, fabric dyes, and finishes. Keeping track of all these materials and processes manually is prone to error and can lead to costly disruptions.

- Real-time inventory upholstery ERP centralizes your inventory data across all warehouses and production units, giving you a live view of what's in stock, what’s reserved for existing orders, and what needs to be reordered. Whether it’s raw materials, semi-finished parts, or finished goods, every item is monitored in real time.

Automated Procurement and Vendor Management:

- In the upholstery industry, delays or inconsistencies from even a single vendor can disrupt the entire production schedule. That’s why automated procurement and vendor management are critical functions of modern ERP software.

- With upholstery ERP, the entire procurement process becomes more streamlined, and data driven. The system tracks usage trends and stock levels and can automatically generate purchase orders when materials reach predefined reorder points. This minimizes the risk of last-minute shortages and helps maintain a steady flow of materials into production.

Integrated Logistics and Order Fulfillment:

- In the upholstery industry, timely and accurate order fulfillment is just as critical as high-quality craftsmanship. Delays in delivery, mismatched products, or missing components can damage customer satisfaction and hurt your reputation. ERP software addresses these challenges by tightly integrating logistics, warehouse operations, and order processing into one seamless workflow.

- With a centralized system, every stage of the fulfillment process is interconnected—right from when the order is placed to when it's shipped and invoiced. This integration reduces communication gaps, manual errors, and operational silos that often slow down traditional upholstery businesses.

Forecasting with Predictive Analytics:

- By analyzing past order trends, seasonality, and market behavior, ERP systems help you plan. This means better demand forecasting, fewer surprises, and smarter resource allocation.

- This forecasting capability allows manufacturers to align procurement, production, and staffing with actual demand patterns. For instance, if data reveals that a particular fabric or sofa model sees higher demand in the winter season, the ERP system can alert production planners to prepare in advance, avoiding delays and stockouts.

Benefits of Using an ERP System

Implementing ERP software brings measurable benefits that directly impact profitability and growth:

- Faster Production Cycles: When materials and workflows are synchronized, products move through production without unnecessary delays.

- Reduced Waste and Cost Control: With accurate data, you can prevent over-ordering and cut down on material waste, leading to better margins.

- Stronger Supplier Relationships: ERP allows for better communication and evaluation of vendors, encouraging reliability and accountability.

- Higher Customer Satisfaction: On-time deliveries, consistent quality, and the ability to handle special requests build trust and encourage repeat business.

- Scalability: As your upholstery business grows, your ERP system scales with you — whether you're adding new product lines, entering new markets, or working with more suppliers.

As the markets are becoming more customer-driven, upholstery manufacturers can’t afford to rely on outdated systems or manual tracking. Supply chain complexity will only increase, and the businesses that thrive will be those that embrace leveraging AI in their upholstery manufacturing processes.

AI integrated ERP software like iTexClouds helps upholstery manufacturers with the tools they need to handle this complexity, from better inventory and vendor management to smarter forecasting and faster order fulfillment. It turns a fragmented supply chain into a well-oiled machine, allowing companies to increase efficiency, reduce costs, and meet evolving customer expectations.

If you're looking to gain full control of your supply chain and grow your upholstery business, an ERP tailored to your needs is no longer optional, it's essential.

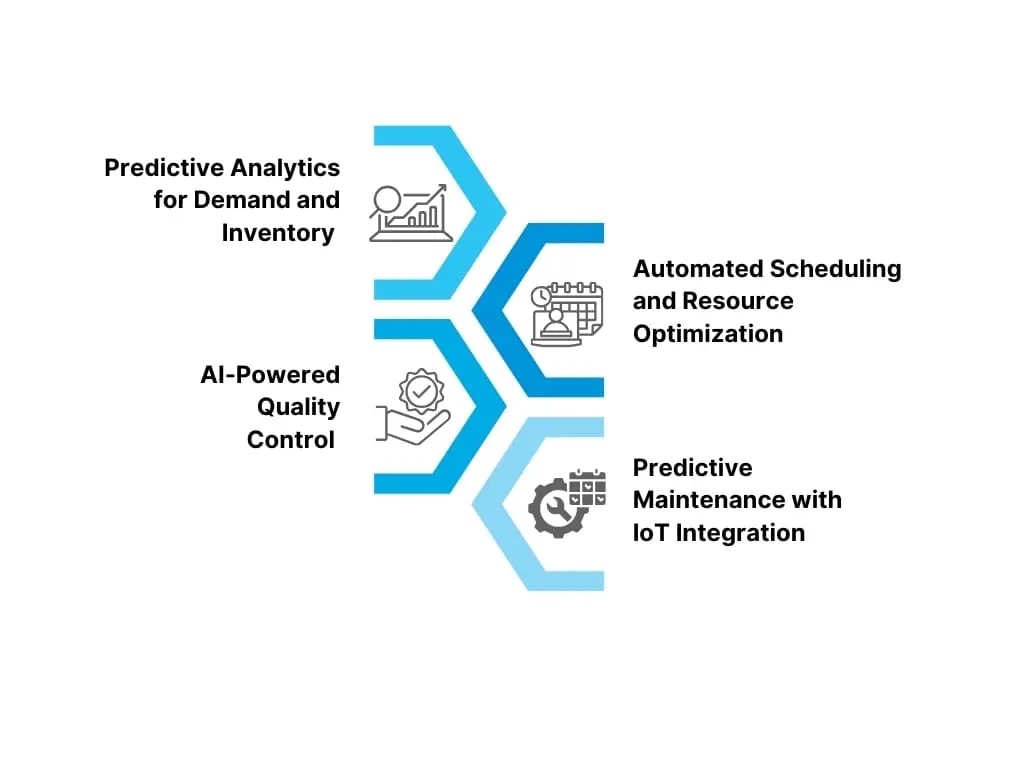

The Evolution of ERP in Upholstery

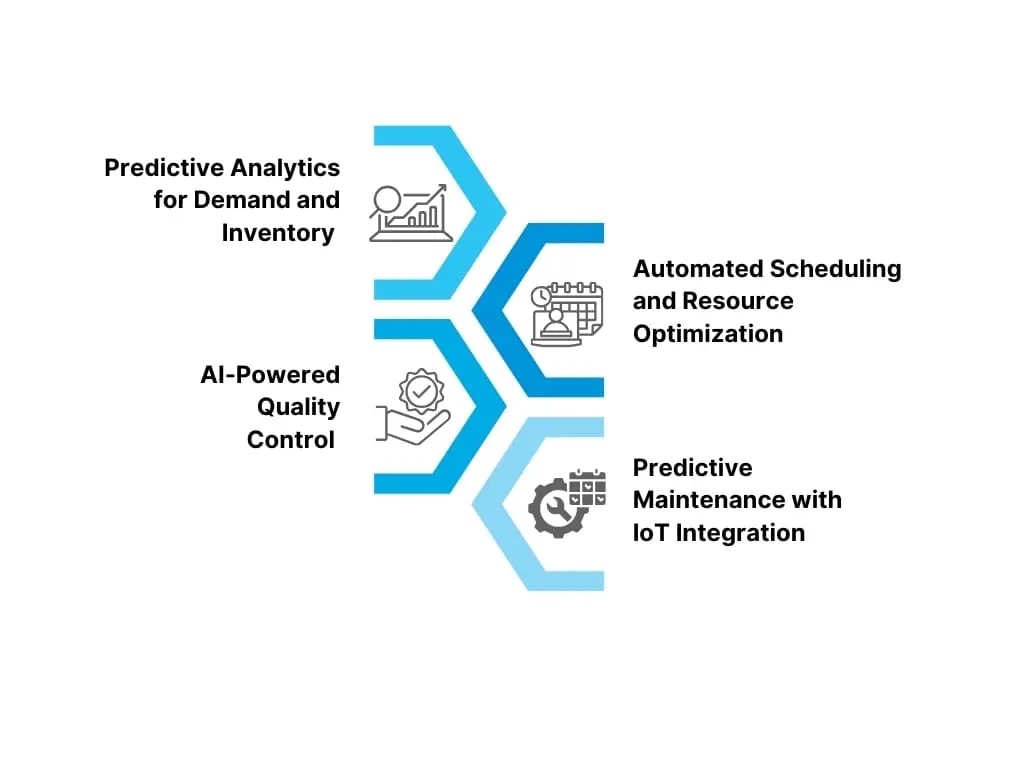

Traditional ERP systems have helped upholstery manufacturers track materials, manage finances, and control production. However, as complexity grows, these systems must move beyond static data management. The integration of AI now enables ERP systems to learn from data, anticipate trends, automate tasks, and make smarter decisions—transforming the role of ERP from a passive data handler to an active business advisor.Key AI Applications in Upholstery ERP

Predictive Analytics for Demand and Inventory

Forecasting demand is one of the most important—and difficult—tasks in upholstery manufacturing. AI upholstery ERP software analyzes historical sales, seasonal patterns, market trends, and even social media signals to predict future demand more accurately. This minimizes stockouts and reduces excess inventory, leading to more efficient operations and improved customer satisfaction.Automated Scheduling and Resource Optimization

Manual scheduling is often inefficient and prone to errors. AI upholstery manufacturing ERP software can dynamically adjust production schedules based on material availability, workforce capacity, and order priority. The result? Improved machine utilization, shorter lead times, and fewer production bottlenecks.Quality Control

Upholstery is all about attention to detail. AI-driven ERP systems can detect quality issues through image recognition and sensor data. Whether it’s a stitching error or fabric inconsistency, the system flags defects in real time, reducing waste and rework.Predictive Maintenance with IoT Integration

Machines are essential to upholstery production, and unexpected downtime can be costly. AI upholstery ERP software with IoT sensors can monitor equipment health and predict maintenance needs before breakdowns occur. This ensures continuous production and extends machine life.Customer-Centric Innovations

- Virtual Reality (VR) Visualization Tools: AI-enabled VR tools allow customers to visualize custom furniture pieces in a virtual setting. This enhances the buying experience and reduces the likelihood of returns or dissatisfaction. Integrated into the ERP, these tools also inform production and inventory decisions based on real-time customer preferences.

- Personalized Recommendations via AI: AI algorithms analyze customer behavior, past purchases, and design preferences to recommend personalized furniture styles, fabrics, and colors. Upholstery manufacturers can use this data not only to boost sales but also to align production with actual demand.

Upholstery Supply Chain Optimization with AI

Managing upholstery supply chains can be incredibly complex, involving multiple suppliers, custom materials, fluctuating demand, and tight delivery schedules.Today, AI upholstery manufacturing ERP systems are helping manufacturers transform their supply chains from reactive to proactive, minimizing delays and maximizing efficiency. Here’s how:Smart Logistics and Route Optimization

With AI-driven logistics optimization, ERP systems analyze real-time traffic patterns, weather forecasts, carrier performance data, and historical delivery trends to find the fastest and most cost-effective delivery routes.Instead of relying on static delivery plans that don't account for sudden disruptions like traffic jams or road closures, AI upholstery tools dynamically reroute shipments to minimize delays. This leads to:- Reduced shipping costs by optimizing fuel consumption and cutting unnecessary transit times.

- Higher delivery rates on time, improving customer satisfaction and strengthening business relationships.

- Better fleet utilization, allowing logistics teams to do more with fewer resources.

- Faster response to disruptions, such as late supplier shipments or last-minute order changes.

IoT-Enabled Adaptive Inventory

Traditional inventory management methods, which often rely on manual counts and static reorder points, are no longer enough.With AI upholstery inventory systems integrated with IoT (Internet of Things) devices across warehouses and production facilities, manufacturers gain real-time tracking of raw materials, components, and finished goods. Smart sensors monitor inventory levels, temperature-sensitive materials, and usage rates of critical supplies.AI algorithms then analyze this live data to:- Automatically adjust reorder points based on current usage rates and forecasted demand rather than sticking to fixed thresholds.

- Predict supply chain disruptions, such as supplier delays or sudden spikes in demand, and alert managers instantly.

- Enable adaptive inventory planning, ensuring manufacturers can maintain a lean inventory while still meeting order commitments.

- Enhance material traceability, which is critical for quality assurance and meeting regulatory requirements.

Future of AI in Upholstery ERP

Emerging Trends: Generative AI and Blockchain

Generative AI is making its way into design and prototyping, allowing AI to create new upholstery designs based on customer feedback and market trends. Meanwhile, blockchain integration in ERP systems could offer traceability and transparency in sourcing materials—especially important for sustainability-conscious customers. Challenges and ConsiderationsDespite its promise, AI implementation isn’t without hurdles. It requires quality data, skilled personnel, and a shift in company culture. Manufacturers must also consider ethical AI use, data privacy, and system integration challenges.AI and Machine Learning in ERP systems are reshaping the upholstery industry by making the systems smarter, faster, and more customer centric. From predicting demand and improving quality control to optimizing logistics and personalizing customer experiences, AI upholstery ERP software is a strategic asset. As technology continues to evolve, upholstery manufacturers that embrace intelligent ERP systems will be better positioned to lead in a highly competitive, ever-changing market.

How Upholstery Manufacturers Can Adapt to Evolving Customer Preferences in 2025

Did you know that over 70% of customers now expect custom furniture options before making a purchase decision? The upholstery market is no longer what it used to be. In today’s fast-paced, style-conscious world, upholstery customer preferences evolve faster than production cycles. Consumers are now driven by personalization, eco-conscious choices, fast delivery, and seamless digital experiences.

For upholstery manufacturers, this shift presents both a challenge and an opportunity. Staying relevant means understanding the new upholstery customer preferences and updating business models to meet rising expectations. Let’s explore how upholstery manufacturers can navigate this evolving landscape successfully.

Understanding Evolving Upholstery Customer Preferences

In today’s fast-changing market, upholstery customer preferences are no longer only limited to comfort and appearance. Modern buyers are influenced by upholstery market trends in sustainability, technology, and lifestyle. To stay relevant, upholstery manufacturers must understand these evolving preferences—what customers prioritize, how they shop, and why they choose one brand over another. This insight is key to developing products that resonate, retain loyalty, and stand out in a highly competitive space.

- Personalization is key – Customers want to choose everything from fabric texture to cushion density and even frame shape. They want custom furniture that reflects their personality.

- Eco-conscious decisions – More buyers prioritize sustainable materials, recycled fabrics, and ethical production.

- Speed and convenience – Long delivery timelines are no longer acceptable. Shoppers want quicker turnarounds with real-time order tracking.

- Tech-savvy expectations – Consumers explore, compare, and customize products online before walking into a store.

- Aesthetics meet functionality – Upholstery is now about form and function—buyers want beautiful, ergonomic, and durable pieces.

These evolving demands require manufacturers to rethink the way they design, produce, and market upholstery products.

Challenges Upholstery Manufacturers Face

Despite growing opportunities, adapting to upholstery customer preferences isn’t easy. Manufacturers often face several hurdles:

- Rigid production systems that aren’t designed for custom orders.

- Sourcing sustainable materials while maintaining cost-efficiency.

- Slow response to upholstery market trends due to limited digital tools or outdated data.

- Disconnected customer experiences between physical showrooms and online platforms.

- Manual processes that slow down delivery and impact customer satisfaction.

Ignoring these challenges means falling behind in a competitive market where customer loyalty is hard to earn and even harder to maintain.

Strategies for Adapting to Upholstery Customer Preferences

Upholstery manufacturers must rethink their traditional processes and embrace change to remain competitive. From product design to customer engagement, every aspect of the business needs to be more agile, responsive, and forward-thinking. To thrive in this dynamic landscape, manufacturers must evolve strategically. Below are five key strategies that can help upholstery businesses stay ahead of the curve and meet modern upholstery customer preferences head-on.

Enable Customization at Scale

- Allow customers to personalize products without slowing down operations.

- Use digital configurators on your website or in-store kiosks.

- Offer a range of fabric, color, and design options with 3D previews.

- Automate order processing for custom configurations.

Embrace Sustainable Materials and Practices

- Make sustainability part of your brand promise.

- Source eco-friendly fabrics like organic cotton, bamboo, or recycled textiles.

- Highlight your efforts through transparent labeling and certifications.

- Use low-VOC adhesives and reduce waste in packaging and shipping.

Speed Up Production with Smart Planning

- Meet delivery expectations with optimized production cycles.

- Implement AI-powered ERP software like iTexClouds for demand forecasting and scheduling.

- Adopt just-in-time inventory to reduce excess and avoid shortages.

- Streamline supplier collaboration to avoid last-minute delays.

Create an Omnichannel Experience

- Connect offline and online touchpoints for a seamless buying journey.

- Integrate showroom visits with online customization tools.

- Offer click-and-collect options or in-store pickups for online orders.

- Ensure consistent product availability and pricing across channels.

Leverage Customer Data and Feedback

- Stay on top of upholstery market trends by listening to what your buyers want.

- Monitor social platforms and design trends regularly.

- Collect customer reviews and conduct short surveys.

- Analyze data to understand popular product combinations and new demands.

Future Trends for Upholstery

Looking ahead, several trends will further shape upholstery manufacturing:- AI and Automation – From virtual assistants helping customers customize furniture to smart inventory systems predicting demand, AI will play a central role.

- Sustainable Innovation – New bio-based materials, zero-waste production models, and energy-efficient factories will define industry leaders.

- AR/VR Shopping Experiences – Augmented reality apps will allow customers to visualize furniture in their space before they buy.

- Smart Furniture – Upholstery with embedded tech for comfort adjustment or health monitoring is on the rise.

- Circular Economy Models – More brands will offer furniture buy-back, recycling, or refurbishment programs to appeal to eco-conscious buyers.

The upholstery industry is undergoing a customer-led transformation. As upholstery customer preferences continue to evolve, manufacturers must go beyond traditional methods and focus on delivering flexibility, sustainability, speed, and digital convenience.

By embracing new technologies, refining production processes, and understanding what today’s customer truly values, upholstery businesses can not only meet expectations—but exceed them. The future belongs to agile manufacturers who are willing to innovate and adapt.

In a market where personalization and purpose matter, now is the perfect time to align your manufacturing strategy with the voice of your customer.

The global upholstery market is projected to surpass $60 billion by 2027, driven by rising demand for customized furniture, eco-conscious materials, and smart home integration. As consumer preferences continue to shift, traditional upholstery processes are being challenged. This is where smart upholstery manufacturing is stepping in—redefining efficiency, quality, and creativity in furniture production. In this blog, we explore how smart technologies are revolutionizing upholstery manufacturing and what it means for the future of the industry.

Advantages of Smart Upholstery Manufacturing

Smart upholstery manufacturing refers to the use of modern technologies like AI, IoT, automation, and data analytics in the production of upholstery materials. These technological advancements enable real-time decision-making, predictive maintenance, custom design integration, and improved material usage. Manufacturers are now moving away from guesswork and manual operations, adopting digital systems that optimize every aspect of the production cycle.

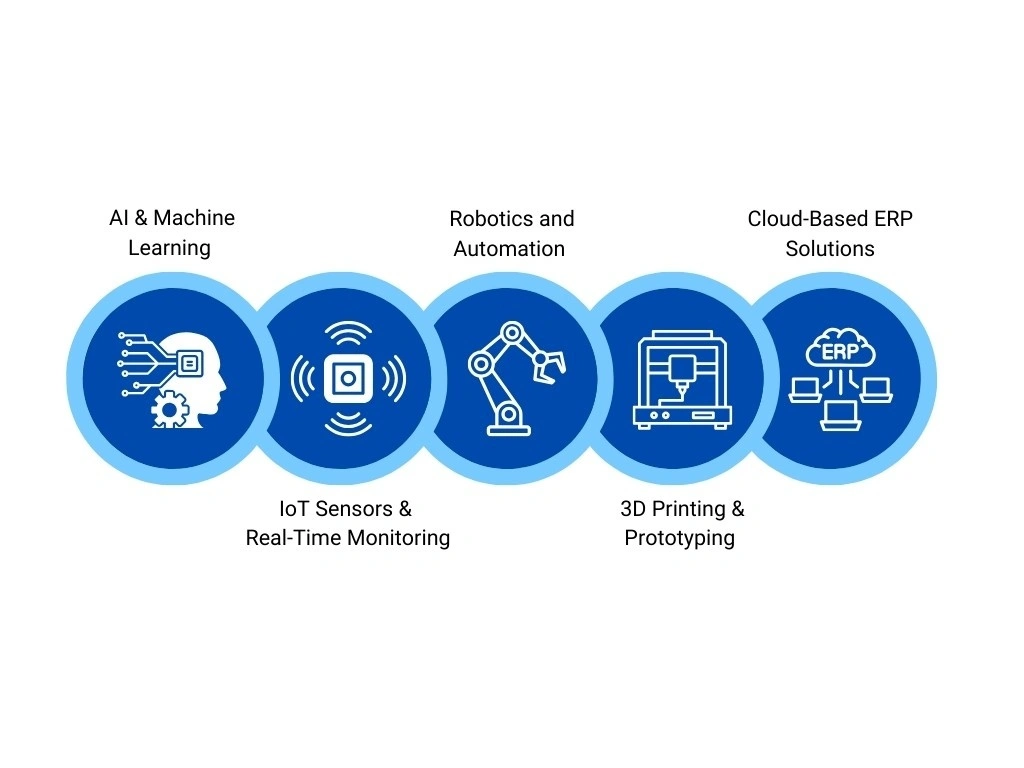

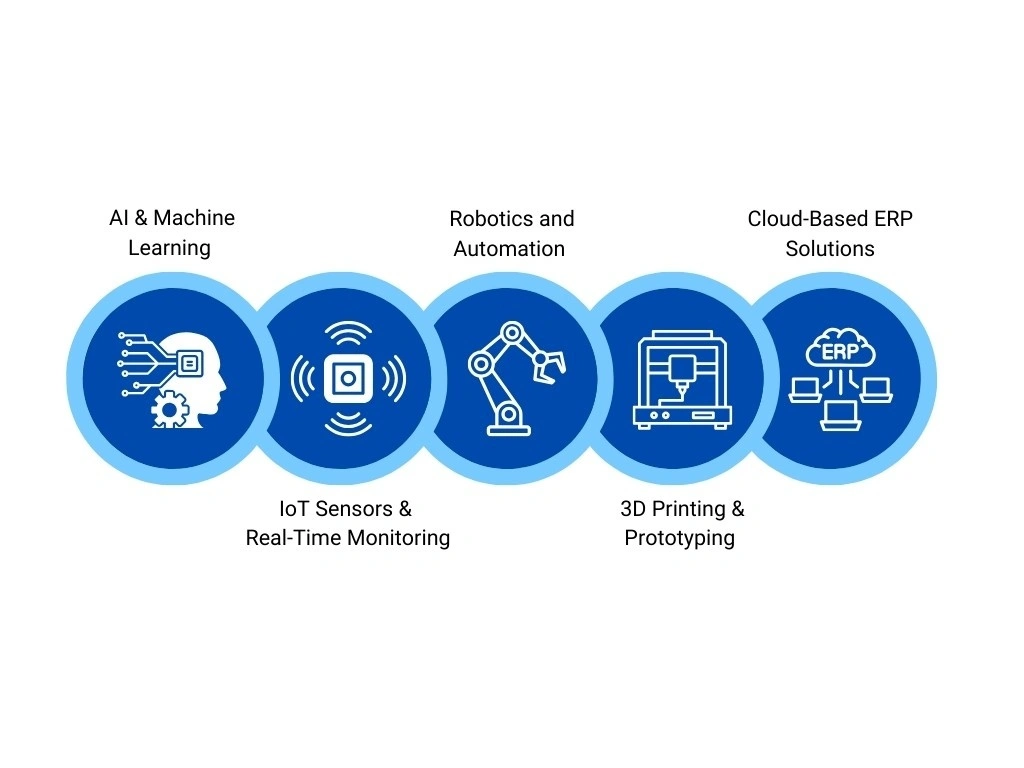

Key Technologies Driving the Transformation

As the upholstery industry undergoes a technological revolution, several advanced systems are emerging as game-changers. These technologies are not only enhancing the speed and accuracy of production but also redefining how manufacturers respond to consumer demands, market trends, and sustainability goals. Let’s take a closer look at the technologies that are driving this transformation:

AI and Machine Learning

AI-powered design software helps manufacturers predict trends, analyze customer behavior, and recommend fabric combinations or patterns that are likely to sell. Machine learning algorithms can also optimize cutting patterns, reducing material waste and speeding up production timelines.

IoT Driven Real-Time Monitoring

Smart sensors attached to machinery can monitor wear and tear, predict failures, and ensure optimal usage. IoT devices also help track the status of every order in real time, improving transparency and reducing communication gaps between teams.

Robotics and Automation

From automated fabric cutters to robotic arms used in stitching or assembling, automation drastically reduces manual labor. This not only improves consistency in product quality but also speeds up large-scale production.

3D Printing and Prototyping

3D printing technology allows for rapid prototyping and testing of new furniture designs. Upholstery manufacturers can experiment with shapes and sizes without incurring huge sample costs or delays.

Cloud-Based ERP Solutions

Modern ERP Systems for Upholstery Manufacturers offer modules for material planning, order tracking, inventory control, and vendor management—all in one platform. Cloud-based access enables real-time collaboration across departments and locations.

Challenges in Adopting Smart Technology

Despite the promise of increased efficiency, quality, and innovation, transitioning to smart upholstery manufacturing comes with its own set of challenges. These obstacles can slow down adoption and create friction across different areas of the business. Understanding these challenges is the first step toward overcoming them:

- High Initial Investment: The cost of implementing IoT, robotics, or ERP systems can be significant.

- Workforce Adaptation: Employees need training to work alongside new technologies and systems.

- Data Integration: Connecting old machinery with new digital tools requires careful planning and compatibility checks.

- Cybersecurity Risks: As operations go digital, protecting company data and production systems becomes crucial.

Benefits of Smart Upholstery Manufacturing

Despite the promise of increased efficiency, quality, and innovation, transitioning to smart upholstery manufacturing comes with its own set of challenges. These obstacles can slow down adoption and create friction across different areas of the business. Understanding these challenges is the first step toward overcoming them:

By embracing smart technologies like an ERP software for upholstery manufacturing, manufacturers can access a wide range of benefits:

- Reduced Production Costs: Automation and real-time data reduce material waste and downtime.

- Improved Quality Control: Consistent monitoring ensures defects are caught early.

- Faster Time to Market: Predictive analytics and AI-assisted planning help meet seasonal demand quicker.

- Enhanced Customization: Digital design tools allow for quick adaptation to consumer preferences.

- Sustainable Production: Optimized material usage and predictive maintenance support eco-friendly practices.

The Future of Upholstery Manufacturing

The adoption of smart technology in upholstery production marks a significant step forward, but it’s only the beginning. As innovation accelerates, the future holds even more exciting developments that promise to reshape the industry on a larger scale. Here’s a look at some of the emerging trends and possibilities that are poised to redefine how upholstery products are designed, manufactured, and delivered:

- AI-powered design assistants recommending entire furniture collections based on customer demographics.

- Voice-activated production lines integrating with smart home systems.

- Sustainable digital twins that simulate production outcomes before any real-world execution.

- Hyper-customization at scale, where customers configure their upholstery pieces online and receive them within days.

As smart homes and AI assistants become part of everyday life, the demand for intelligent, well-designed, and responsive upholstery will only grow.

Smart upholstery manufacturing is no longer a futuristic concept—it’s happening now. By leveraging technologies like AI, IoT, robotics, and cloud ERP systems, upholstery manufacturers are cutting costs, improving quality, and adapting faster to consumer demands. Though challenges exist, companies that begin adopting these technologies today will be better positioned to lead the market tomorrow.

In 2025 and beyond, the winners in the upholstery industry will be those who innovate with purpose, embrace data-driven decisions, and commit to building smarter, more responsive operations.

In the competitive world of apparel manufacturing, efficiency, precision, and adaptability are critical for success. Managing production processes effectively ensures timely deliveries, cost control, and superior product quality. This is where software like apparel production management software or apparel distribution software comes in handy.

Designed to streamline workflows and optimize operations, these systems help manufacturers overcome challenges like fluctuating demand, resource constraints, and market competition. This blog highlights five key features that make this software a game-changer for apparel manufacturers.

5 Key Features of Apparel Production Management Software

Apparel ERP production management software optimizes operations, reduces errors, and boosts productivity in the textile industry. With features designed to improve resource management, streamline processes, and meet customer demands, this software helps manufacturers stay competitive.

Here are five key features that enhance operational efficiency and deliver high-quality products.

1] AI Production Planning and Scheduling :

AI-driven production planning and scheduling is one of the major features that has revolutionized how textile businesses operate all their planning and scheduling processes. AI-driven production planning and scheduling in an apparel ERP helps textile manufacturers automate resource allocation, track progress, and predict bottlenecks.

Textile manufacturers often struggle with inaccurate production forecasts, inefficient resource allocation, and communication breakdowns between departments. These issues lead to delays, increased costs, and wasted resources.

With an AI featured apparel production management software, manufacturers can optimize machine utilization, manage workforce shifts efficiently, and account for variables like order size and raw material availability. These intelligent planning tools reduce delays, eliminate waste, and improve overall productivity, ensuring operations run smoothly even during unforeseen disruptions.

2] Advanced Reporting and Analytics :

Knowing every detail regarding the production, schedule and status of each textile process before making a business decision is key. To optimize the decision-making process of textile manufacturers, advanced reporting and analytics tools provide actionable insights into production timelines, costs, and performance metrics.

Textile manufacturers often face challenges such as tracking fragmented data, identifying process inefficiencies, and making data-backed decisions in real time. These hurdles can lead to missed opportunities, increased costs, and slower responses to market demands.

Using an ERP for apparel manufacturers can track key performance indicators (KPIs) like order fulfillment rates, defect percentages, and lead times. These insights allow businesses to identify inefficiencies, forecast future production needs, and make strategic adjustments to improve their bottom line.

3] Customizable Dashboards :

Every apparel business operates differently, with unique processes and priorities. Apparel production management software must be able to provide customizable dashboards, allowing manufacturers to see reports specific to their needs.

Textile manufacturers often face challenges with generic reporting systems that fail to reflect specific operational intricacies. For example, predefined templates might omit critical metrics such as seasonal sales variations or vendor delivery efficiency. This leads to fragmented insights and hampers the ability to make precise, data-backed decisions.

Whether it’s tracking fabric consumption, monitoring seasonal order trends, or analyzing supplier performance, customizable dashboards enable teams to focus on the metrics that matter most. This flexibility enhances transparency across departments, fosters better collaboration, and supports data-driven decision-making.

4] Advanced Reporting and Analytics :

Managing costs is a constant challenge in apparel manufacturing, especially with rising material and labor expenses. A robust budgeting and cost control feature in ERP for textile industry is essential for maintaining profitability while delivering high-quality products.

Apparel manufacturers frequently face challenges like unexpected cost overruns caused by poor expense tracking and inaccurate budget planning. Issues such as fluctuating raw material costs or unplanned overtime labor can threaten financial stability.

With apparel production management software, manufacturers can forecast budgets, track real-time expenses, and monitor cost variances. This ensures that projects stay within financial limits while identifying potential savings. The software also helps calculate production costs accurately, making it easier to price products competitively without compromising on quality.

5] Sales Order Integration:

Sales order integration bridges the gap between customer demand and production planning. This feature ensures that customer orders are seamlessly translated into actionable production schedules, improving efficiency and customer satisfaction.

Textile manufacturers often face challenges like delayed or incomplete order information, which disrupts production timelines and leads to missed deadlines. Managing urgent orders without proper prioritization or resource allocation can further complicate operations.

By using apparel production management software with integrated sales order management, businesses can prioritize urgent orders, allocate resources accordingly, and track order statuses in real-time. This alignment minimizes errors, reduces lead times, and ensures on-time deliveries, fostering stronger relationships with clients and retailers.

The apparel manufacturing industry is evolving, and staying competitive requires investing in the right tools. Apparel production management software offers features like AI-driven production planning, advanced analytics, and cost control that streamline operations, reduce waste, and enhance productivity.

By integrating these tools into their workflows, apparel manufacturers can overcome industry challenges, meet customer demands, and achieve long-term success. Choosing software tailored to your business needs sets the foundation for efficient and profitable production in today’s dynamic market.

Did you know that inefficient order management costs the apparel industry billions annually? Efficiently managing orders isn’t just a challenge—it’s a transformative opportunity to thrive in a competitive landscape. The apparel sector is notorious for its complexities: fluctuating consumer demands, diverse product lines, strict deadlines, and the pressure to deliver with precision. Missteps in managing these intricacies can result in bottlenecks, customer dissatisfaction, and stagnated growth.

Apparel order management software offers a comprehensive solution by streamlining processes, enhancing accuracy, and enabling businesses to adapt to changing market dynamics. But before diving into how this technology can drive growth, let’s first understand the pressing issues that businesses face in apparel order management—issues that this software is uniquely equipped to solve.

Common Challenges in Apparel Order Management

Despite advancements in technology, apparel businesses continue to grapple with recurring issues that hinder efficiency and growth.

Here are 10 common issues in apparel order management:

- Inventory Management Challenges – Overstocking or understocking due to inaccurate demand forecasting.

- Order Tracking Inefficiencies – Lack of real-time visibility and manual tracking errors.

- Production and Delivery Delays – Misaligned schedules and bottlenecks causing delays.

- Poor Communication and Coordination – Inefficient communication between teams and customers.

- Customization Complexities – Difficulty managing personalized or made-to-order requests.

- Inaccurate Sales Forecasting – Misjudging demand, leading to missed opportunities.

- High Return Rates – Quality issues or incorrect shipments causing returns.

- Manual Processes – Time-consuming, error-prone manual workflows.

- Resource Allocation Issues – Poor utilization of materials, labor, and equipment.

- Lack of Scalability – Difficulty managing growing order volumes and expanding markets.

11 Ways Apparel Order Management Software Helps Solve These Problems

The above challenges underscore the need for a robust ERP for apparel, such as order management software that streamlines operations and addresses inefficiencies effectively. Let’s explore how apparel order management software addresses these problems while driving growth.

1] Streamlining Order Processing :

Apparel manufacturers handle a multitude of order variations. ERP for garment manufacturing or apparel order management software automates key processes like order entry, validation, and tracking.

By eliminating manual tasks such as data entry and order validation, businesses can streamline workflows, reduce bottlenecks, and ensure smooth fulfillment from order placement to delivery.

2] Real-Time Inventory Tracking :

Stockouts and overstocking are one of the leading concerns in the textile industry as the market trends keep changing. Apparel inventory management software provides real-time updates on inventory levels, enabling businesses to manage stock effectively.

This not only prevents costly issues like stockouts or overstocking but also directly impacts profitability by reducing excess inventory costs and improving order fulfillment speed—ultimately enhancing customer satisfaction. With accurate data at their fingertips, businesses can avoid costly errors and capitalize on demand opportunities.

3] Improved Order Accuracy:

Errors in order processing results in dissatisfied customers and increased returns. Apparel order management software minimizes these errors by automating data entry and integrating with other systems. This accuracy drastically reduces operational costs associated with fixing mistakes like variations in textile order size, color, design, etc.

By standardizing order information and eliminating manual input errors, businesses can significantly reduce inaccuracies, streamline workflows, and deliver orders that meet or exceed customer expectations.

4] Enhanced Customer Communication :

Clear and consistent communication with customers is vital for building strong relationships. Order management software enables businesses to provide real-time updates on order status, estimated delivery times, and any potential delays.

Customers can receive automated notifications, access detailed order histories, and even track their orders online. This level of proactive communication boosts customer satisfaction, reduces complaints, and encourages repeat business, fostering stronger client relationships.

5] Integration with Other Systems :

Apparel order management software integrates seamlessly with other software systems such as an apparel production planning software, inventory software, etc., creating a unified ecosystem that ensures smooth information flow and enhanced operational efficiency.

This interconnected approach enables better cross-department coordination, reduces manual handoffs, and enhances visibility into each step of the supply chain. Businesses can leverage this integration to optimize workflows, identify bottlenecks, and improve overall productivity.

6] Dynamic Order Prioritization :

Handling multiple orders simultaneously can be challenging, especially when urgent or high-value orders come in. Apparel Order management software incorporates advanced algorithms that allow businesses to categorize and prioritize orders based on factors such as value, urgency, or delivery deadlines.

High-value or urgent orders can be processed efficiently without disrupting ongoing workflows, ensuring timely delivery and high levels of client satisfaction.

7] Optimized Resource Allocation :

Efficient resource allocation is critical in apparel manufacturing, where materials, labor, and machinery need to work in harmony. ERP for apparel analyzes production requirements, workforce availability, and machinery capacities to allocate resources effectively.

This ensures balanced workloads, minimizes resource wastage, and maximizes productivity. With better resource allocation, businesses can meet tight deadlines while maintaining high-quality standards and controlling costs.

8] Better Sales Forecasting :

Apparel order management software leverages historical data and current trends to forecast demand accurately. This foresight helps businesses optimize production schedules, align inventory with anticipated demand, and prepare for peak sales periods.

Improved forecasting also minimizes the risk of overproduction or underproduction, helping businesses stay agile and responsive to market changes.

9] Reduced Operational Costs :

By automating processes and minimizing errors, apparel order management software significantly reduces operational costs. Businesses save on labor costs by reducing manual interventions, avoid penalties for late deliveries, and minimize the expenses associated with product returns. These savings can be reinvested into other areas of the business, fostering growth and innovation.

10] Customizable Reporting and Analytics :

Data-driven decision-making is key to sustainable growth in the apparel industry. Apparel Order management software or ERP for garment manufacturing provides customizable dashboards and advanced analytics, offering insights into order trends, production efficiency, and customer preferences. These insights empower leaders to make informed strategic decisions, optimize processes, and align resources with business goals.

11] Scalability for Business Expansion :

As businesses grow, managing higher order volumes becomes challenging. Apparel Order management software scales seamlessly, accommodating new product lines, markets, and customer demands without compromising efficiency. Its adaptability ensures that businesses can expand operations, enter new markets, and handle increased complexity with confidence.

Apparel order management software is a vital tool for manufacturers aiming to achieve sustainable growth in a competitive market. By streamlining order processing, improving accuracy, and integrating seamlessly with other systems, this software addresses the unique challenges of the apparel industry.

Its features, such as dynamic prioritization, real-time inventory tracking, and advanced analytics, empower businesses to make data-driven decisions and adapt to changing demands. Investing in a robust order management solution ensures that businesses are well-equipped to deliver exceptional results, foster customer loyalty, and achieve long-term success.

Apparel manufacturing is an industry that demands precision, speed, and flexibility. To stay competitive in today’s market, manufacturers require advanced apparel manufacturing software like an ERP system that caters to their unique needs. A well-designed ERP for apparel manufacturing not only manages operations seamlessly but also empowers businesses to meet customer demands, reduce costs, and scale efficiently.

This blog will explore the challenges faced by apparel manufacturers in today’s textile market and how ERP software can offer the ultimate solution. These features are designed to optimize productivity, improve decision-making, and address the growing complexities of the industry.

Challenges Faced by Apparel Manufacturers

The modern textile and apparel industry is evolving rapidly, and manufacturers often find themselves grappling with a host of challenges that hinder their ability to thrive. Dealing with these challenges requires the right help and expertise.

Let’s take a closer look at these challenges:

- Rising Costs: The cost of raw materials continues to increase, and labor shortages are adding financial pressure, reducing profit margins.

- Fluctuating Demand: Unpredictable fashion trends and changing consumer behavior make demand forecasting more complex.

- Sustainability Pressures: Consumers are increasingly prioritizing eco-friendly and sustainable products, adding another layer of complexity to production processes.

- Supply Chain Disruptions: Delays, inefficiencies, and external factors, such as global logistics challenges, negatively impact production schedules.

- Inventory Management Issues: Managing vast inventories of diverse fabrics, colors, trims, and other materials often leads to overstocking or critical shortages.

- Tight Delivery Deadlines: With growing competition, customers demand quicker turnarounds, putting added pressure on manufacturers to meet deadlines.

- Lack of Integration: Disconnected systems lead to inefficiencies, errors, and a lack of visibility into operations, resulting in reduced competitiveness.

4 Features of ERP for Apparel Manufacturers

Addressing the above challenges are critical for survival and growth. Apparel manufacturing software with the right features can provide comprehensive solutions to these problems while helping businesses operate with greater efficiency and agility.

Here are the four must-have features that you must look out for:

1] Comprehensive Inventory Management:

Efficient inventory management is an absolute necessity for apparel manufacturers as they are always dealing with a variety of fabrics, colors, and trims. For this, the apparel manufacturing software should include:

- Real-time inventory tracking

- Automated replenishment alerts

- Detailed material categorization

These features help textile manufacturers to maintain an optimal balance of stock, minimize waste, and prevent delays in production schedules.

For example, real-time inventory insights help manufacturers quickly identify fabric shortages and reorder materials before production halts. This level of control not only reduces material waste but also enables smoother production cycles.

In addition, these tools streamline inventory management for complex orders involving multiple fabric types and trims, ensuring seamless operations from start to finish.

2] Integrated AI Production Planning and Control:

Production planning is one of the most intricate aspects of apparel manufacturing, involving processes such as cutting, sewing, assembly, and quality control. Managing these processes effectively is essential to ensure on-time delivery.

The apparel manufacturing software must offer:

- Integrated Tools for Production Scheduling

- Capacity Planning

- Workflow Monitoring

What sets advanced ERP systems apart is their ability to leverage AI-powered production scheduling. This feature dynamically adjusts schedules to accommodate unexpected disruptions, such as supplier delays or urgent customer orders.

For instance, if a customer places a last-minute high-priority order, the AI-driven system can reallocate resources and adjust the production schedule automatically, minimizing disruptions. This agility ensures manufacturers meet tight deadlines while maintaining high-quality standards.

3] Dynamic Supply Chain Management:

The apparel industry thrives on collaboration across a vast supply chain, involving suppliers, vendors, and logistics partners. Delays or inefficiencies in any segment can impact overall productivity.

A robust textile ERP software must provide end-to-end visibility across the entire textile supply chain by offering features like:

- Supplier performance tracking

- Order monitoring

- Cost analysis tools

By integrating supply chain data from various sources, apparel manufacturing software eliminates silos and creates a unified workflow. Manufacturers gain end-to-end visibility into their operations, enabling them to make informed decisions quickly.

For example, real-time supply chain data can help businesses identify delays in raw material deliveries and take proactive steps to mitigate disruptions, ensuring production schedules stay on track.

4] Advanced Reporting and Analytics:

In an industry where trends evolve rapidly, data-driven decisions are vital for success. Apparel manufacturers need tools that provide actionable insights to optimize operations and forecast demand accurately.

An ERP system with advanced analytics offers:

- Customizable dashboards

- Predictive modeling

- Real-time reporting

These features enable businesses to track KPIs, such as production efficiency and customer satisfaction, and identify areas for improvement.

For instance, analyzing sales trends through ERP-generated reports enables manufacturers to align production schedules with consumer demand, reducing waste and improving profitability. Additionally, predictive analytics helps manufacturers prepare for seasonal demand fluctuations, ensuring they can meet market needs efficiently.

ERP for textile industry plays a pivotal role in streamlining operations, enhancing efficiency, and driving business growth. Features like inventory management, production planning, supply chain visibility, and advanced analytics are essential for addressing the unique challenges of this industry.

By adopting tailored apparel manufacturing software, businesses can adapt to changing market demands, reduce operational complexities, and achieve long-term success. Investing in the right technology today ensures that businesses remain competitive and ready for the future.

The textile industry is evolving rapidly, with trends like sustainable manufacturing, real-time decision-making, and global supply chain optimization reshaping operations. To stay competitive, textile manufacturers need the best apparel management software to manage everything from production to inventory and customer relationships.

However, with a wide range of solutions available, choosing the right textile ERP software can feel overwhelming. The key is to focus on tools that align with your unique business goals and offer long-term scalability.

This blog explores nine essential tips for selecting the right ERP system to help your business thrive in 2025 and beyond.

1] Understand Your Business Needs:

Every textile business has unique requirements, whether it’s managing bulk orders, handling diverse product lines, or ensuring quality consistency.

When choosing the best apparel management software make sure it aligns with your operational challenges. An ERP software for textile industry must be customizable so that it is able to support various workflows and provide modules that can be tailored to your specific needs.

This ensures that textile manufacturers can manage inventory and production processes accurately while seamlessly integrating the ERP with existing systems. This integration eliminates gaps in functionality and ensures a smooth transition.

2] Prioritize Scalability:

As your business grows, your ERP should evolve to accommodate the increased production, new customers, and expanded markets in 2025. Scalability is especially important as businesses expand their operations to meet growing market demands and explore new opportunities.

The best apparel management software must be able to adapt to a textile business’s scaling needs.

A textile ERP software offering scalability enhances operational flexibility, allowing manufacturers to increase production and sales without requiring frequent upgrades or replacements. This ensures businesses can meet growth demands efficiently.

3] Evaluate Integration Capabilities:

In the textile industry, manufacturers rely on multiple tools and systems to manage design, production, inventory, and supply chain operations. Without proper integration, these systems can create data silos and workflow inefficiencies.

The best apparel management software for 2025 should seamlessly integrate with tools like CAD software for textile design, inventory management systems, and maintenance tools such as CMMS. Integration ensures smooth data flow across departments, enhances collaboration between design, production, and sales teams, and provides a unified operational view. This allows manufacturers to optimize processes, reduce errors, and improve overall efficiency.

4] Focus on Real-Time Data Accessibility:

In 2025 the textile market is predicted to be the most competitive it has ever been, so having up-to-date information can make or break your business operations.

The best apparel management software for 2025 must provide real-time data dashboards. Textile manufacturing ERP software must allow manufacturers to monitor yarn inventory, track fabric production timelines, and check customer order statuses instantly. This capability is invaluable for making timely, informed decisions and staying ahead of market changes.

5] Check for Industry-Specific Features:

As the textile industry heads into 2025, evolving demands require ERP solutions tailored to its unique workflows.

The best apparel management software should include features designed for yarn and fabric tracking, dyeing and finishing processes, and production timeline monitoring. These industry-specific capabilities help businesses address sustainability goals and supply chain complexities effectively. A textile-focused ERP not only ensures seamless operations but also positions businesses to meet future trends as well.

6] Ensure User-Friendly Interfaces:

As businesses prepare for 2025, textile manufacturers will need apparel software solutions that simplify complex operations with intuitive interfaces.

Textile ERP should offer dashboards that are easy to navigate, minimizing training time for employees and ensuring quick adoption. User-friendly features like drag-and-drop scheduling, visual inventory tracking, and customizable reports are vital for enhancing productivity. A straightforward interface allows teams to focus on core operations rather than wrestling with complicated software, providing a competitive edge in the fast-paced textile industry.

5] Verify Vendor Support and Training:

As ERP systems evolve with new functionalities and technological advancements, robust vendor support and training become essential for businesses to adapt effectively.

The best apparel management software should come with dedicated support teams available 24/7 to address technical issues promptly. Look for vendors offering comprehensive onboarding and training resources, such as user manuals, video tutorials, and live workshops, to ensure your team can leverage the software effectively. Continuous updates and reliable customer service ensure your ERP remains aligned with changing business needs and technological advancements.

8] Focus on Cost and ROI:

In the competitive textile market, investing in ERP software requires balancing upfront costs with long-term returns—a strategic priority for 2025.

The best apparel management software should offer transparent pricing models and demonstrate measurable ROI, such as reduced waste, improved efficiency, or increased revenue. Choose software that aligns with your budget while offering features that drive cost savings, enabling your business to justify the investment and stay ahead of competitors.

9] Consider Sustainability Features:

Sustainability is set to dominate textile industry priorities in 2025. Adopting ERP software with sustainability at its core demonstrates your commitment to responsible practices, enhancing your brand reputation and attracting eco-conscious clients.

The best apparel management software should include features to track ESG compliance, reduce waste, and optimize energy usage. Tools for monitoring eco-friendly raw materials and managing recyclable packaging align with both regulatory requirements and customer preferences.

In 2025, choosing the best apparel management software is more critical than ever for textile manufacturers. The ideal ERP system can streamline operations, enhance decision-making, and help you adapt to ever-changing market demands.

By following these nine tips, you’ll be empowered to choose a solution that not only improves efficiency and reduces costs but also supports scalability and sustainability. With the right tools in place, your business can thrive, stay competitive, and lead the way in a rapidly evolving textile landscape.

- All Resources

- Blog

- Customer Story

The upholstery industry is evolving fast in 2025 and is predicted to grow at a CAGR of over 5.5%, reaching $27.58 billion by 2030. With rising customer expectations, tighter delivery timelines, and growing demand for customization, upholstery businesses must rethink how they operate.

Relying on outdated methods is no longer sustainable or optimum. That’s where upholstery manufacturing ERP software plays a key role. It helps streamline operations, reduce errors, and improve margins across every stage of production and delivery.

Challenges of Sticking to the "Traditional Ways"

Manual Inventory Errors and Stock Shortages

Upholstery production involves a wide range of materials that are involved in a wider range of processes every step of the way. So, without an automated system, tracking materials becomes a huge task and also prone to a lot of errors. Missing raw materials or overstocking cuts into profits leading to unnecessary delays.

Inconsistent Production Planning and Delays

Paper-based schedules or spreadsheets have their advantages, but they definitely can’t keep up with fluctuating orders and workforce changes that always happen in upholstery manufacturing. Paper-based schedules are also prone to physical damage or tampering, creating a good chance for bottlenecks and missed deadlines to occur.

Lack of Real-Time Customer and Order Data

Traditional systems don’t offer a full picture of customer interactions or order histories. To keep up with the current upholstery market trends, knowing what your customers’ preferences are plays a huge role. Without real-time customer and order data, it limits the ability to personalize service and predict future upholstery demands.

Poor Supply Chain Visibility

Managing suppliers and vendors in an old-fashioned way creates a lot of opportunities for communication gaps. If your suppliers, vendors, and internal teams aren’t connected through a unified system, there will always be a lack of visibility on the upholstery supply chain. This will inevitably lead to errors in customer orders and delivery issues.

Inefficient Cost Tracking and Budgeting

Keeping track of financial data through manual methods is always a tedious task. When it comes to upholstery manufacturing or upholstery production, it gets even more tricky. Without centralized financial data, it's hard to track costs accurately or understand where resources are being wasted.

Key Features of an Upholstery ERP Software for the 2025 Market

Real-Time Inventory and Material Tracking

In textile upholstery manufacturing, managing a wide variety of fabrics, threads, linings, and embellishments can be overwhelming. An ERP system offering inventory management features help with real-time visibility into raw materials, in-process fabrics, and finished goods.

These tools centralize stock data from cutting, stitching, and finishing units, ensuring you never run out of high-demand fabrics or slow-moving ones. With instant updates on stock levels and automated reorder alerts, production teams can operate with fewer delays and tighter inventory control.

AI-Based Production Scheduling and Optimization

Fabric upholstery often involves made-to-order designs with varying textures, colors, and finishes - making production planning more complex. An upholstery manufacturing ERP integrated with AI helps simplify this by automatically creating and adjusting schedules based on order priority, machine availability (like cutting or sewing stations), and material readiness.

This helps to reduce manual planning errors, prevent bottlenecks in fabric handling and processing, and ensure timely order fulfillment, even in high-mix, low-volume production setups.

Built-in Quality Control

An upholstery manufacturing ERP with integrated quality control modules allows manufacturers to define quality checkpoints - whether it’s fabric strength, color consistency, or stitching precision.

These checkpoints are tracked throughout the production process, with real-time alerts for defects or deviations. This ensures that only materials meeting set standards move forward, reducing costly rework and returns. With better visibility into quality metrics, manufacturers can uphold brand standards and improve customer satisfaction over time.

Smart Supplier and Vendor Management

Sourcing fabrics, threads, dyes, and trims from multiple suppliers comes with challenges - especially when quality and lead time directly affect production timelines. An upholstery manufacturing ERP helps manage supplier performance by tracking delivery accuracy, pricing, and defect rates.

With these insights, manufacturers can make informed sourcing decisions, minimize disruptions, and ensure they’re always working with reliable partners. During fabric shortages or price fluctuations, the system helps you quickly identify alternate suppliers without compromising deadlines.

Advanced Analytics and Forecasting Tools

Textile upholstery manufacturing must respond to trends in color, texture, and consumer preferences - often with little notice. Advanced ERP analytics help you spot these trends early by analyzing historical order patterns, seasonal demand, and fabric usage rates.

Whether you're preparing for a seasonal surge in velvet sofas or responding to growing interest in sustainable fabrics, forecasting tools give you the edge. You can better align procurement, optimize fabric rolls, and plan workforce allocation - all while keeping costs in check.

Results You Can Expect

By adopting an upholstery manufacturing ERP such as iTexClouds, businesses can expect more than just automation. You gain end-to-end visibility, improve collaboration, and respond faster to customer needs. Teams spend less time fixing errors and more time focusing on growth. Profit margins increase through better planning, fewer delays, and optimized resource use. Most importantly, you stay competitive in a rapidly changing market.

The upholstery market in 2025 is defined by speed, precision, and personalization. To meet these demands, manufacturers must leave behind traditional workflows. Implementing a powerful ERP system is no longer a luxury. It’s a strategic move to stay relevant, efficient, and profitable.

In the process of upholstery manufacturing, managing upholstery supply chains is by far the most tedious to handle. Over 56% of U.S. furniture manufacturers report persistent difficulty in sourcing materials and managing supplier timelines, particularly for upholstery-grade textiles and foam. From sourcing unique fabrics to fulfilling highly customized orders, managing the upholstery supply chain involves a lot of complications. As customer expectations grow and global operations become more intricate, upholstery manufacturers are turning to technologies such as ERP software to bring clarity, control, and consistency to their upholstery supply chains.

Key Supply Chain Issues Faced by Upholstery Manufacturers

Supply chain management in upholstery manufacturing involves a vast array of materials. Each order often demands a different combination of these components, along with specific colors, finishes, and delivery timelines. As product personalization increases, the need to manage this complexity becomes even more critical. Let’s look at the major pain points that can slow down or disrupt upholstery supply chains:

- Inventory Mismatches and Material Shortages: Manual tracking often leads to inaccurate stock counts, resulting in delays or excess holding costs.

- Delayed Shipments and Order Backlogs: Without centralized scheduling, overlapping orders or supplier delays can quickly create bottlenecks.

- Lack of Real-Time Coordination: Production, procurement, and sales often operate in silos, leading to miscommunication and misalignment.

- Vendor Unreliability and Quality Inconsistencies: When supplier performance isn’t monitored, late deliveries and quality issues become common.

How ERP Software Streamlines Upholstery Supply Chains

Modern ERP software is designed to integrate and optimize every part of the upholstery supply chain. Here’s how it makes a difference:

Real-Time Inventory Tracking

- One of the most valuable features of ERP software in managing complex upholstery supply chains is real-time inventory tracking. Supply chain management in upholstery involves dozens of components — different fabrics, stitching styles, fabric dyes, and finishes. Keeping track of all these materials and processes manually is prone to error and can lead to costly disruptions.

- Real-time inventory upholstery ERP centralizes your inventory data across all warehouses and production units, giving you a live view of what's in stock, what’s reserved for existing orders, and what needs to be reordered. Whether it’s raw materials, semi-finished parts, or finished goods, every item is monitored in real time.

Automated Procurement and Vendor Management:

- In the upholstery industry, delays or inconsistencies from even a single vendor can disrupt the entire production schedule. That’s why automated procurement and vendor management are critical functions of modern ERP software.

- With upholstery ERP, the entire procurement process becomes more streamlined, and data driven. The system tracks usage trends and stock levels and can automatically generate purchase orders when materials reach predefined reorder points. This minimizes the risk of last-minute shortages and helps maintain a steady flow of materials into production.

Integrated Logistics and Order Fulfillment:

- In the upholstery industry, timely and accurate order fulfillment is just as critical as high-quality craftsmanship. Delays in delivery, mismatched products, or missing components can damage customer satisfaction and hurt your reputation. ERP software addresses these challenges by tightly integrating logistics, warehouse operations, and order processing into one seamless workflow.

- With a centralized system, every stage of the fulfillment process is interconnected—right from when the order is placed to when it's shipped and invoiced. This integration reduces communication gaps, manual errors, and operational silos that often slow down traditional upholstery businesses.

Forecasting with Predictive Analytics:

- By analyzing past order trends, seasonality, and market behavior, ERP systems help you plan. This means better demand forecasting, fewer surprises, and smarter resource allocation.

- This forecasting capability allows manufacturers to align procurement, production, and staffing with actual demand patterns. For instance, if data reveals that a particular fabric or sofa model sees higher demand in the winter season, the ERP system can alert production planners to prepare in advance, avoiding delays and stockouts.

Benefits of Using an ERP System

Implementing ERP software brings measurable benefits that directly impact profitability and growth:

- Faster Production Cycles: When materials and workflows are synchronized, products move through production without unnecessary delays.

- Reduced Waste and Cost Control: With accurate data, you can prevent over-ordering and cut down on material waste, leading to better margins.

- Stronger Supplier Relationships: ERP allows for better communication and evaluation of vendors, encouraging reliability and accountability.

- Higher Customer Satisfaction: On-time deliveries, consistent quality, and the ability to handle special requests build trust and encourage repeat business.

- Scalability: As your upholstery business grows, your ERP system scales with you — whether you're adding new product lines, entering new markets, or working with more suppliers.

As the markets are becoming more customer-driven, upholstery manufacturers can’t afford to rely on outdated systems or manual tracking. Supply chain complexity will only increase, and the businesses that thrive will be those that embrace leveraging AI in their upholstery manufacturing processes.

AI integrated ERP software like iTexClouds helps upholstery manufacturers with the tools they need to handle this complexity, from better inventory and vendor management to smarter forecasting and faster order fulfillment. It turns a fragmented supply chain into a well-oiled machine, allowing companies to increase efficiency, reduce costs, and meet evolving customer expectations.

If you're looking to gain full control of your supply chain and grow your upholstery business, an ERP tailored to your needs is no longer optional, it's essential.

The Evolution of ERP in Upholstery

Traditional ERP systems have helped upholstery manufacturers track materials, manage finances, and control production. However, as complexity grows, these systems must move beyond static data management. The integration of AI now enables ERP systems to learn from data, anticipate trends, automate tasks, and make smarter decisions—transforming the role of ERP from a passive data handler to an active business advisor.Key AI Applications in Upholstery ERP

Predictive Analytics for Demand and Inventory

Forecasting demand is one of the most important—and difficult—tasks in upholstery manufacturing. AI upholstery ERP software analyzes historical sales, seasonal patterns, market trends, and even social media signals to predict future demand more accurately. This minimizes stockouts and reduces excess inventory, leading to more efficient operations and improved customer satisfaction.Automated Scheduling and Resource Optimization

Manual scheduling is often inefficient and prone to errors. AI upholstery manufacturing ERP software can dynamically adjust production schedules based on material availability, workforce capacity, and order priority. The result? Improved machine utilization, shorter lead times, and fewer production bottlenecks.Quality Control

Upholstery is all about attention to detail. AI-driven ERP systems can detect quality issues through image recognition and sensor data. Whether it’s a stitching error or fabric inconsistency, the system flags defects in real time, reducing waste and rework.Predictive Maintenance with IoT Integration

Machines are essential to upholstery production, and unexpected downtime can be costly. AI upholstery ERP software with IoT sensors can monitor equipment health and predict maintenance needs before breakdowns occur. This ensures continuous production and extends machine life.Customer-Centric Innovations

- Virtual Reality (VR) Visualization Tools: AI-enabled VR tools allow customers to visualize custom furniture pieces in a virtual setting. This enhances the buying experience and reduces the likelihood of returns or dissatisfaction. Integrated into the ERP, these tools also inform production and inventory decisions based on real-time customer preferences.

- Personalized Recommendations via AI: AI algorithms analyze customer behavior, past purchases, and design preferences to recommend personalized furniture styles, fabrics, and colors. Upholstery manufacturers can use this data not only to boost sales but also to align production with actual demand.

Upholstery Supply Chain Optimization with AI

Managing upholstery supply chains can be incredibly complex, involving multiple suppliers, custom materials, fluctuating demand, and tight delivery schedules.Today, AI upholstery manufacturing ERP systems are helping manufacturers transform their supply chains from reactive to proactive, minimizing delays and maximizing efficiency. Here’s how:Smart Logistics and Route Optimization

With AI-driven logistics optimization, ERP systems analyze real-time traffic patterns, weather forecasts, carrier performance data, and historical delivery trends to find the fastest and most cost-effective delivery routes.Instead of relying on static delivery plans that don't account for sudden disruptions like traffic jams or road closures, AI upholstery tools dynamically reroute shipments to minimize delays. This leads to:- Reduced shipping costs by optimizing fuel consumption and cutting unnecessary transit times.

- Higher delivery rates on time, improving customer satisfaction and strengthening business relationships.

- Better fleet utilization, allowing logistics teams to do more with fewer resources.

- Faster response to disruptions, such as late supplier shipments or last-minute order changes.

IoT-Enabled Adaptive Inventory

Traditional inventory management methods, which often rely on manual counts and static reorder points, are no longer enough.With AI upholstery inventory systems integrated with IoT (Internet of Things) devices across warehouses and production facilities, manufacturers gain real-time tracking of raw materials, components, and finished goods. Smart sensors monitor inventory levels, temperature-sensitive materials, and usage rates of critical supplies.AI algorithms then analyze this live data to:- Automatically adjust reorder points based on current usage rates and forecasted demand rather than sticking to fixed thresholds.

- Predict supply chain disruptions, such as supplier delays or sudden spikes in demand, and alert managers instantly.

- Enable adaptive inventory planning, ensuring manufacturers can maintain a lean inventory while still meeting order commitments.

- Enhance material traceability, which is critical for quality assurance and meeting regulatory requirements.

Future of AI in Upholstery ERP

Emerging Trends: Generative AI and Blockchain