9 Key Considerations for a Smooth Textile ERP Migration

Planning to migrate to a new textile ERP solution but apprehensive about the meticulous process? Migrating to a new ERP software is a critical decision that can significantly impact your textile business’s growth and efficiency. It can lead to improved and streamlined processes, better data management practices, increased productivity, and informed decision-making. While the ERP market is expected to reach USD 78.4 billion by the end of 2026, as high as 50-70% of ERP implementation projects fail. Therefore, having a well-planned ERP migration strategy is crucial to ensure a successful and smooth transition.

Let us go over 9 important things textile manufacturers must keep in mind before embarking on an ERP migration.

Top 9 Things to Consider Before Enterprise Application Migration

As per research, it is found out that 83% of ERP migration strategies either exceed the deadline or the estimated budget. In worst case scenarios, some projects even lead to a complete failure. So, as a textile manufacturer, what can you do to avoid such costly mistakes?

Here are the 9 things you must consider before you start your ERP migration process:

Your Business Needs

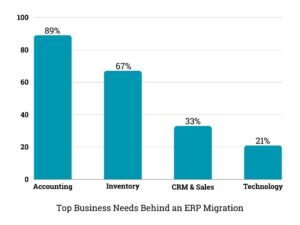

Having a clear understanding of the business needs is the steppingstone towards a successful ERP migration. Identify the limitations of your existing data management systems and define clear objectives for the new solution.

As a textile manufacturer, you must consider aspects like inventory control, production planning, jobwork planning, supply chain, etc. Once you identify the primary areas that need improvement, you would be able to find an ERP that will address these specific issues. It will also help you specify the limitations of your existing system and help you refine your search for the new ERP solution.

Defined Strategy

As per a report, 45% of companies undergoing ERP migration exceeded their planned budget, while 58% of them exceeded their planned timeline. Therefore, creating a well-defined strategy that outlines your project scope, budget, timeline, Key Performance Indicators (KPIs), etc., is crucial. It should also adequately address the intricacies of the textile industry.

Depending on the pain points of your business, you must set clear objectives like improving production cycles, streamlining inventory management, quality control, etc. Having a well-defined strategy in place will also allow you to keep track of the migration process and ensure it meets the desired budget and timelines.

Migration Team

Your migration team is integral to the entire enterprise application migration process. They must have the necessary skills, experience, and should be ready to allocate 50% of their time in the migration process. The success or failure of the migration will primarily depend on them. Hence, ensure assembling a diverse team by including experienced stakeholders from various sections of your textile business.

Make sure the migration strategy is well-communicated to all the stakeholders of the project and they are on the same page. Take into account all the insights they might offer to ensure the long-term success of the ERP.

Data Cleaning

When migrating to a new ERP solution, you must strictly avoid migrating all of your data from your existing system to the new system. Invest time and effort in data cleaning to ensure accurate and reliable data migration in ERP. Remember, this is the best time for you to identify faulty, obsolete, or duplicate data.

Prioritize cleaning data related to raw materials, finished goods, available resources, and customer information. Additionally, ensure that historical data related to fabric quality and production defects is carefully analyzed and cleansed to improve decision-making and quality control.

Data Mapping

41% of companies have cited data issues to be the biggest reason behind their delay in ERP migration project. Have a proper strategy in plan to align data structures between the old and new ERP system. It will help you ensure smooth data transfer while ensuring timelines. It will also help you to minimize data discrepancies and ensure data consistency in the new system.

In textile manufacturing, data mapping is essential to ensure seamless migration of inventory details, batch records, sales order information, etc. Accurate data mapping guarantees smooth production processes, minimizing errors in material allocation and production planning.

Continuous Testing

Data migration in ERP cannot be successful without testing during the migration phase. In fact, lack of testing is considered among the top 2 reasons for failure in ERP migration. This is because unidentified issues in the migration, such as variations in raw material or production data, may lead to extensive rework in the long run.

Therefore, comprehensive testing is vital to identify and resolve issues early in the migration process. Regularly test the data migration process to ensure that data is accurately transferred from the old system to the new one. Thorough testing will minimize the risk of disruptions during the go-live phase.

Customizations Needed

You cannot fully leverage an ERP system until you customize it as per your business requirements. As per data, up to 82% of organizations opt for customization during the ERP migration process. While opting for textile-focused ERP solutions is a wise idea, you may still need to customize it as per your specific requirements. Taking care of the customizations during the ERP migration ensures a smooth run after implementation.

However, you must also remember that opting for too many customizations may lead to complexities during system upgrades. Try to strike a balance between the customizations and the standard features of the textile ERP to ensure ease of maintenance and optimum system performance.

Data Governance

A successful ERP migration depends on a chunk of data being transferred from one system to another. To avoid any disruptions, discrepancies, etc., it is essential for you to establish a strong data governance framework. This includes defining data ownership, data access controls, etc.

The textile industry is a complex ecosystem, and each set of data is relevant to a specific team. Hence, establishing proper data governance rules is necessary to ensure the correct team gets access to correct data. Again, being one of the most important ERP data migration best practices, data governance ensures data consistency and traceability throughout the supply chain.

Employee Training

Employees are the end-users of the ERP. Hence, investing in comprehensive employee training is crucial to ensure a smooth functionality of the ERP. In addition, given the complexities of the textile industry, your employees may need additional support from you to understand the functioning of the ERP.

Develop training materials, provide hands-on practice sessions, encourage employees to ask questions. Effective training will boost user adoption and enable your organization to reap the full benefits of the new textile ERP solution.

Migrating to a new ERP solution in the textile industry demands a comprehensive understanding of industry-specific requirements and challenges. By considering the nine key factors outlined in this tailored guide, textile manufacturers can optimize their ERP migration process and enhance operational efficiency, quality control, and compliance in their production processes. A successful ERP migration will empower textile manufacturers to stay competitive, meet customer demands, and drive growth in the dynamic textile market.