How to estimate your textile ERP ROI?

Investing in an Enterprise Resource Planning (ERP) system is a crucial decision for any textile manufacturing business. As this sector involves complex processes like production planning, inventory management, quality control, etc., an ERP solution can greatly increase their productivity, reduce costs, save time, and automate processes.

With the Enterprise Resource Planning software market for the textile industry growing at a CAGR of 11.3%, textile businesses should evaluate the potential ROI of an ERP implementation before investing.

Estimating the ROI of your ERP implementation in the textile industry involves a careful analysis of costs, benefits, and intangible factors. In this blog, we will guide you through the process of evaluating your ERP ROI, ensuring that you make an informed decision that aligns with your organization’s goals.

How to Calculate Return on Investment (ROI) from Textile ERP?

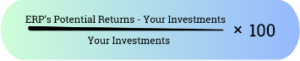

The process of ROI calculation of your textile ERP implementation is simple and primarily involves two things:

- Your investments (the total cost associated with software ownership, operation, and implementation)

- The ERP’s potential returns

Using the following ROI formula, you can get an estimate of the possible returns from your ERP investment:

However, that is not all. There are several other factors that need to be considered to ensure that the derived results are useful and valid.

However, that is not all. There are several other factors that need to be considered to ensure that the derived results are useful and valid.

Reasonable Forecast Period:

Considering a reasonable forecast period is crucial when calculating ERP ROI. Generally, a forecast period of 3-5 years is considered ideal. This period allows enough time to implement the ERP system, train employees, and start seeing tangible benefits in the form of increased efficiency and reduced costs.

- Taking into account a longer period may result in decreased accuracy of predictions due to changing business needs, fluctuations in raw material availability, costs, and technology.

- On the other hand, a successful ERP implementation leads to better inventory management, improved production planning, etc., but these benefits are gradual. Hence, a shorter forecast period may not capture the full benefits and result in inaccurate results.

Choice of Deployment Model:

Factoring in the deployment model to calculate return on investment of your textile ERP is crucial as different models have different cost structures. For example, cloud ERP systems may cost you almost 30% less than on-premises ERPs.

- Cloud-based ERP systems are viable options for fabric manufacturers looking to scale quickly or for those who lack the technical infrastructure and expertise to support on-premises deployments. Cloud ERP systems typically have lower upfront costs and shorter implementation times, and they incur operating expenses (OpEx) that are spread over time, making them cost-effective in the long run. As a result, it is estimated that almost 53% of businesses using ERP opt for cloud-based deployment.

- On the other hand, for larger textile corporations with IT infrastructure and more complex and specific needs, on-premises ERP solutions might be the preferred choice. On-premises ERPs offer more control and data security, which might appeal to certain businesses. However, they come with higher initial costs and longer implementation timelines. Additionally, they require ongoing post-installation maintenance, resulting in capital expenses (CapEx).

Consider Tangible & Intangible Benefits:

Not all benefits derived from an ERP implementation in a textile business can be quantified. Some are intangible and significantly contribute to an ERP’s long-term benefits.

- Tangible benefits (hard ROI) are quantifiable and directly measurable outcomes that lead to cost savings or increased revenue.

- Intangible benefits (soft ROI), on the other hand, are challenging to quantify but equally important.

| Tangible Benefits | Intangible Benefits |

| Streamlined allocation of resources | Improved cross-team collaboration |

| Reduced inventory of costs | Increased customer satisfaction |

| Better management of equipment | Systematic workflows |

| Decreased labor expenses | Legal & regulatory compliance |

| Less WIP time | Accurate maintenance of various records |

Be Realistic:

The textile industry is complex and dynamic. Therefore, when estimating textile ERP ROI, it’s essential to be realistic about the potential benefits and costs. Take into account past experiences, industry benchmarks, and feedback from ERP vendors or other companies that have implemented similar systems.

- The benefits received from a textile ERP are gradual and takes some time. Hence, having over-optimistic projections can lead to disappointments if the expected returns are not achieved.

- Conversely, lower projections can lead to underuse of the ERP and may result in continued inefficiencies in the textile manufacturing process, lost opportunities, and time.

Pre and post installation usage:

Any standard ERP implementation process involves two stages, both significantly contributing to an ERP’s return on investment. Consider both before estimating your textile ERP ROI to ensure you derive accurate results.

- The costs associated with the pre-installation stage are related to planning the implementation, setting up the required hardware or software, migrating data from any existing system, etc. Vendor support plays a crucial role in all this as they provide the expertise and customization needed to fit the specific needs of your textile business.

- Once the ERP system is live, the post-installation phase begins, and this involves costs related to user training, system maintenance, upgrades, and additional customization. Given the complexities involved in the textile business, proper training and system maintenance is essential to ensure ease of use and optimum utilization of the ERP.

Role of ROI Calculators in Calculating Textile ERP ROI

ROI calculators simplify complex financial calculations by considering multiple scenarios. These user-friendly calculators provide a structured framework for inputting data, automatically performing calculations, and comparing potential outcomes. By assessing various scenarios, decision-makers can identify the most viable ERP approach based on risk levels and business strategies.

Estimating textile ERP ROI is a complex process that requires careful consideration of various factors. By selecting a reasonable forecast period, choosing the appropriate deployment model, and accounting for both tangible and intangible benefits, you can create a more comprehensive and accurate ROI analysis.

Being realistic in your projections and evaluating pre- and post-installation usage will help ensure that the derived results are meaningful and valuable for making informed business decisions. Remember that ROI calculation of a textile ERP system is not just about immediate financial gains. It’s also about enhancing organizational efficiency and competitiveness in the long run.