Excel Sheet: A Risky Foundation for Your Business Operations

With a projected value of $3 Trillion by 2030, the global textile industry is continuously growing. As this industry is expanding, it is becoming increasingly complex and data intensive. Therefore, businesses operating within the textile sector must establish efficient data management processes to stay competitive.

Traditionally the textile industry has relied on excel sheets, to handle their data. While excel has remained a staple in the industry for a long time, with advancing technology, Enterprise Resource Planning (ERP) systems have been gaining popularity due to their ability to integrate multiple facets of business operations.

This blog aims to cover the multiple aspects of Excel vs ERP for textile industry, and why the manufacturers must choose ERP as their textile software.

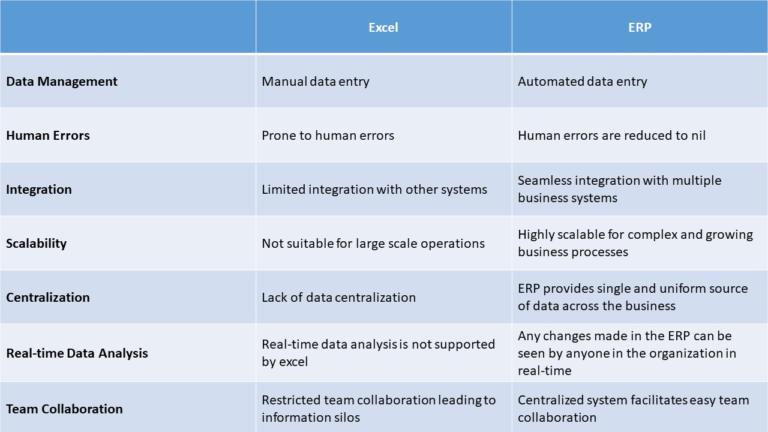

Excel vs ERP: Quick Differences

Need for ERP in the Textile Industry

Insufficient use of appropriate technology has significantly contributed to the textile industry’s struggle with low-capacity utilization as low as 40-50%. This can be attributed to the industry’s complex nature, involving multiple processes like order processing, production planning, procurement, inventory management, finance management, and so much more. These generate vast amounts of data that textile manufacturers must accurately capture, analyze, and utilize to make informed business decisions. Not doing so can lead to inefficient operations, financial bottlenecks, etc. Hence, it becomes imperative for the industry to adopt suitable technological solutions that effectively manage this vast amount of data.

Let’s take a look at some reasons why the textile industry needs an efficient ERP system:

1. Handle Inventory Data: The textile industry heavily depends on efficient handling of inventory data such as stock, levels, demand forecasting and procuring as per need, etc. Without proper management of inventory data, textile manufacturers can suffer from unforeseen losses, increased wastage, stockouts, and so much more. Hence, textile software is crucial for manufacturers to keep track of inventory and take decisions proactively.

2. Handle Order Processing: Order processing is a crucial and complex aspect of textile manufacturing that involves a large amount of data. These include accurate order entry, order confirmation, planning materials and resources to complete a particular order, etc. ERP software used in textile industry allows manufacturers to carry out these tasks seamlessly and meet their delivery timelines.

3. Manage Finances: A complete textile production cycle, right from receiving orders to settling invoices, generates a lot of financial data that must be maintained. Inaccuracy in this may lead to issues in balance sheets, financial losses, invoicing troubles, etc. Textile software solves all these issues and enables manufacturers to keep track of all their finances efficiently.

4. Increased Visibility: Complete business visibility is crucial for textile manufacturers to ensure streamlined operations, optimum utilization of resources and timely order processing. ERP software ensures manufacturers stay up to date with all data related to every aspect of their business. This transparency helps identify bottlenecks, minimize delays, and improve overall efficiency.

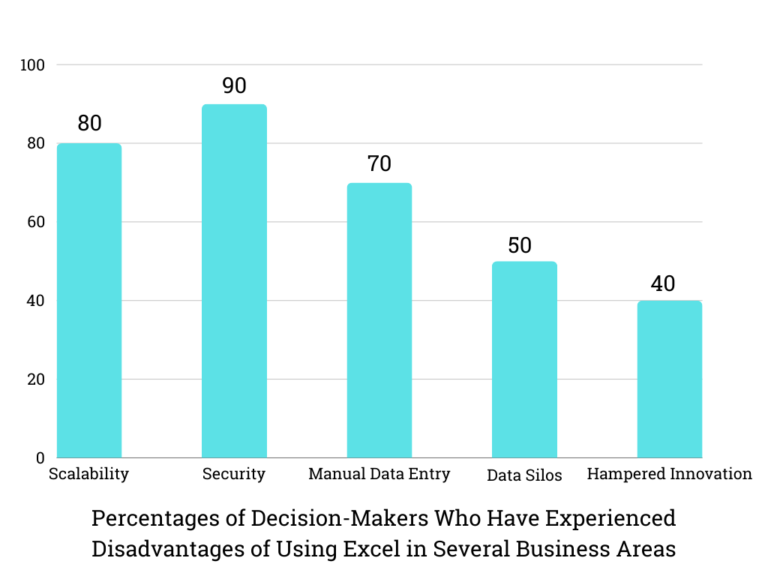

Limitations of Excel for the Textile Industry

While Excel has been a popular tool for data management, it has several limitations that make it inadequate for the complex needs of the textile industry:

Manual Data Entry: Excel requires manual data entry, making it prone to human errors, duplication, and inconsistencies. In the textile industry, where accuracy is crucial for managing vast inventories and supply chains, relying on manual processes can result in costly mistakes.

Lack of Integration: Excel operates as a standalone tool and lacks seamless integration with other systems. This makes it challenging to consolidate data from different sources and limits the ability to automate processes, leading to inefficient workflows.

Limited Scalability: Excel is not designed to handle large volumes of data and complex operations. As textile businesses grow, they face challenges in scaling their data management processes using Excel, resulting in increased time consumption and decreased efficiency.

Lack of Real-time Updates: Excel operates in a static environment where data updates are manual. In the textile industry, where real-time visibility is crucial for efficient decision-making, Excel’s lack of real-time updates can lead to outdated information and misinformed decisions.

Complex Data Analysis: Excel has limited capabilities for complex data analysis, making it challenging to derive meaningful insights from large datasets. In the textile industry, where analyzing trends, forecasting demand, and optimizing production processes are critical, ERP systems offer advanced analytics tools for more sophisticated analysis.

Advantages of ERP Over Excel for the Textile Industry

The global textile ERP market is experiencing significant growth, with a promising compound annual growth rate (CAGR) of 10.2%. By the year 2026, it is projected to reach a substantial market value of $78.4 billion. In the textile industry, the implementation of textile ERP systems offers numerous advantages over relying solely on Excel:

Automated Data Management: ERP systems automate data entry, processing, and reporting, reducing human errors and ensuring data integrity. This automation saves time and resources, allowing employees to focus on more value-added tasks.

Seamless Integration: ERP for textile industry offers seamless integration with various modules, such as finance, production, inventory, and sales. This integration enables real-time data exchange, eliminates duplicate data entry, and provides a holistic view of the entire textile business.

Demand Planning and Forecasting: ERP systems provide robust demand planning and forecasting capabilities. By analyzing historical data, market trends, and customer insights, textile businesses can accurately predict demand, optimize production schedules, and minimize stockouts or overstock situations.

Efficient Resource Allocation: ERP systems enable effective resource allocation in the textile industry. By integrating production planning with inventory management, businesses can optimize resource utilization, minimize waste, and enhance overall operational efficiency.

Customization Options: Unlike Excel, textile ERP systems offer extensive customization options. Textile businesses can tailor the system to their specific requirements, incorporating industry-specific features and workflows. This flexibility enhances operational efficiency and supports unique business processes.

Streamlined Financial Management: ERP systems streamline financial management processes in the textile industry. They automate invoicing, payment tracking, and financial reporting, reducing manual errors and facilitating accurate financial analysis. This helps textile businesses gain better control over their finances and make informed financial decisions.